Electrical heating type pilot glass-lined reactor Guangzhou Jinzong Machinery

*Chemical Pilot Reactor

The whole system of glass-lined pilot reactor consists of micro glass-lined reaction kettle, tower section, chip condenser, storage tank and glass-lined pipeline, and equipped with the corresponding external cycle oil bath heating temperature control system and mixing frequency control system. To complete the reaction, reflux, distillation and other processes. Is the fine chemicals, bio-pharmaceutical, new materials, the ideal pilot and production equipment.

1.Capacity 5L-200L.

2.Including jacketed reactor,condenser,storage tank,conduction oil preheating tank,hot oil pump,pipelines,valves,temperature gauge PT100,pressure gauge,platform etc.

3.Glass-lined type.

4.Heating and cooling by jacket or heated by jacket and cooling by inner pipe coil

*Model selection reference of reaction kettle

Composition | Instructions |

| Specification (L) | 5-200 |

| Design Pressure (Mpa) | Atmospheric Pressure or under pressure |

| Material | enamel |

| Heating Forms | Electrical heating with medium in jacket, external half coil steam heating, external half conduction oil heating, hot water infrared heating etc. |

| Cooling Forms | Refrigeration medium in the internal pipe jacket |

| Blending Power | Model selection is made according to material viscosity, liquid-solid ratio, liquid specific gravity, solid specific gravity, solid granularity, rotation speed, paddle type, with or without baffle or internal coil. |

| Stirring blade Forms | Anchor type, frame type, flat paddle type, pitched paddle type, ribbon type, turbo type, pusher type and multiple compound type |

| Seal | Mechanical seal or stuff packing seal |

| Inner Surface Treatment | Polished or no polished |

| Discharge Valve | Flanged ball valve, open downward discharge valve and others |

| Technological Pipe Hole | Manhole, sight glass, distillation mouth, imported materials, pressure gauge port, temperature, mouth, mouth filling N2, |

*Glass-lined plate type condenser:

| Model | Number of plate type condenser | Heat exchange area m2 | DN | D | B | ~H | d | Weight Kg |

| W0.25 | 4 | 0.75 | 350 | 200 | 120 | 500 | 18 | 90 |

| 5 | 1 | 600 | 100 | |||||

| 6 | 1.25 | 700 | 110 | |||||

| 7 | 1.5 | 800 | 120 |

*Technical Parameter

| Symbol | 5L | 10L | 20L | 30L | 40L | 50L |

| a | Dg70/50 | Dg70/50 | Dg70/50 | Dg70/50 | Dg70/50 | Dg70/50 |

| b1,b2 | Dg20 | Dg20 | Dg20 | Dg20 | Dg20 | Dg20 |

| c1,c2 | Dg50 | Dg50 | Dg50 | Dg50 | Dg50 | Dg50 |

| d1,d2 | Dg50 | Dg50 | Dg50 | Dg50 | Dg50 | Dg50 |

| e | Dg50 | Dg50 | Dg50 | Dg50 | Dg50 | Dg50 |

| D | 250 | 250 | 300 | 400 | 400 | 500 |

| D1 | 350 | 350 | 400 | 500 | 500 | 600 |

| ~H | 430 | 500 | 580 | 620 | 730 | 756 |

| H1 | 366 | 447 | 524 | 562 | 672 | 682 |

| H2 | 186 | 275 | 344 | 382 | 492 | 456 |

| Weight Kg | 98 | 110 | 120 | 135 | 145 | 160 |

Nozzle size

| Symbol | DN | Application | Remark |

| a1 | 50 | Heat source inlet | Meet HGJ45-91PN0.6 standard |

| a2 | 50 | Heat source outlet | |

| b1 | 20 | Cooling water inlet | Meet HGJ45-91PN0.6 standard |

| b2 | 20 | Cooling water outlet |

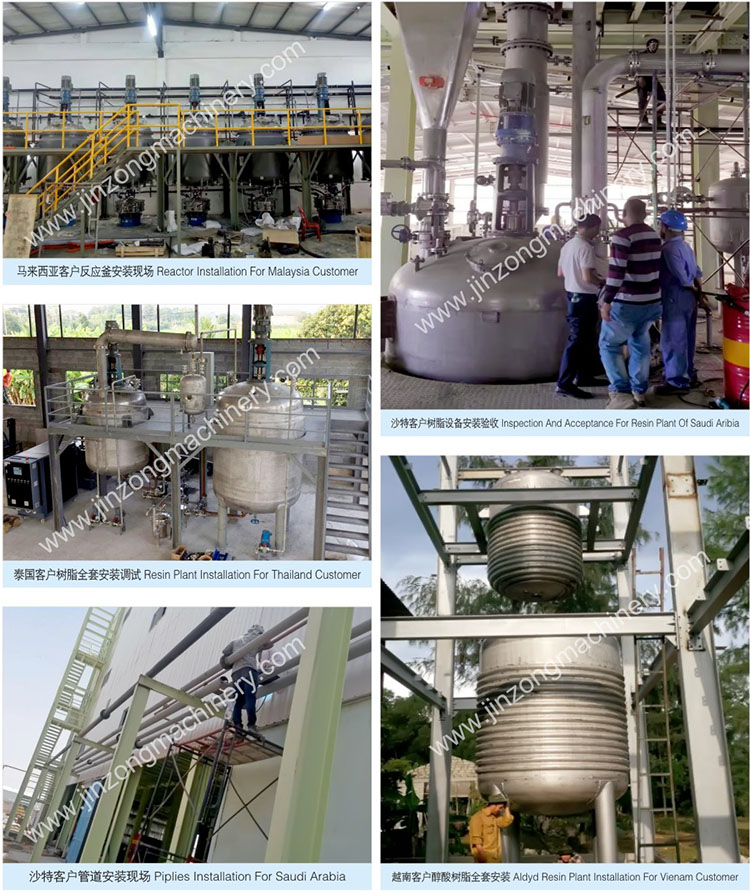

*Resin plant is manufacturing in our factory:

*Our company can provide users with engineering design, equipment model selection guide, equipment machinig, equipment installation and turn-key project. *Advantage

*Advantage

For more than 20 years Guangzhou Jinzong Machinery Co., Ltd. has developed cost effective solutions and innovative processes for the production of high quality synthetic resins and polymer emulsions for Asia , Middle East, and South America.

Jinzong Machinery has in-house capabilities to both upgrade existing synthetic resin and polymer emulsion manufacturing plants and design new ones with state of the art process control systems.

offers a full range of engineering services to the resin, paint, plastic and printing ink industries including :

Feasibility studies

Process control system software upgrades

Existing facility improvements

Turnkey plants

*After-sales service:

*After-sales service:

1> one year from date of delivery, if any spare parts be broken within warranty and not caused by improperly operation, we would offer the new parts for free.

2> Provide professional after-sales service engineers to abroad installation and debugging.

*ONE-STOP SERVICES

According to market and customer demands, our company is continuously researching, developing, upgrading and improving various products, striving to build the firs "one-stop" type cosmetic machinery shopping with machinery & equipment, cosmetic raw material, packing materials, technical consultation and other services

*Providing technical support in the aspects of field commissioning and running of the products sold.

*Field failure diagnosis and maintenance.

*Providing spare parts and fittings, maintenance and servicing plans.

*Choosing Jinzong Machinery is choosing professional technical support and good after-sales service.

*About us:

Guangzhou / Guangdong Jinzong Machinery Co., Ltd. is a professional manufacturer of cosmetic,chemical, biological & pharmaceutical machinery and equipment more than 20 years .

Jinzong Machinery is a technology innovative enterprise focusing on machinery design, manufacturing and system integration.

Product lines range from:

1> Cosmetic Machinery: water treatment ,vacuum emulsifying machine,liquid detergent mixing machine,storage tank,solid soap making machine,perfume making machine, color paste mill, filling machine etc.

2> Chemical Machinery: reactor, mixing equipment, separation equipment, storage tank, disperser, mill etc.

3> Biological and Pharmaceutical Machinery: vacuum ointment machine, fermentation tank, sanitary stainless reactor,alcohol deposition can, collocation tank etc.

*Our strength

1. More than 20 years extensive experience in the machinery manufacturing in Cosmetic and cheimical biological & pharmaceutical industry.

2. Quality, 80% materials and components are purchased from 3M, ABB, Siemens, Panasonic, Schneider. Up to now, all core machinery are with CE Certificate. We carry out products designing, manufacturing, assembling and detection fully in accordance with ISO9001-2008 Quality Management System issued by Swiss SGS Company.

3. Good reputation in industry. Many years are awarded "defend the contract heavy credit enterprise"

4.Have a Professional after-sales service engineering team.

5.Large scale plant. Currently, we have 2 processing bases, Zhaoqing factory, covering a total area of more than 17,000 square meters,and Shaoguan factory,covering a total area of more than 30,000 square meters. There are more than 160 sets of processing machinery including large vertical lathe, 5-axis horizontal machining center, large planer type milling machine, automatic polishing machines etc. With the help of our strong processing capacity, we produce more than 1000 sets of equipment every year

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist