Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

durable chemical machine complete manufacturer for distillation

- Jinzong insists on the service concept that we give priority to customer and service. Under the guidance of market, we strive to meet customers' needs and provide quality products and services.

1. This type of chemical machine uses such materials with lab reactor properties.

2. Through the use of advanced testing equipment in products, many quality problems can be found in time, thus effectively improving the quality of products.

3. This product is the first choice of our customers, with long service life and practicality.

4. Some customers told us that they really appreciate the seam and stitching the product is made. It is not easily fray even it is used heavily.

5. Investing in this product can help save money on a long term basis. It only needs little maintenance and care to run effectively.

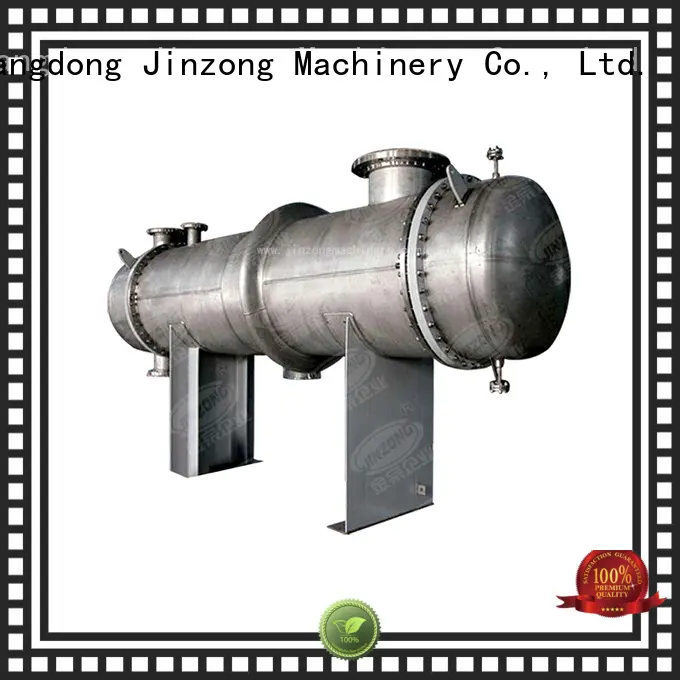

The heat exchanger is used for heat transfer between the material . With this device so that the material can reach the specified temperature to meet the technical requirements. Using a combination of various heat exchanger, can use a variety of levels of energy fully and rationally, so that reduce unit product energy consumption, thereby reducing the cost of the product to get good value .

Heat exchanger can be divided into two categories according to the device structure namely,plate-and-frame type heat exchanger and shell and tube heat exchanger. Chip plate heat exchanger is combination of plate-fin and shell-type spiral.Shell and tube heat exchanger is a compostion of shell and tube plate devices.

The tubular condenser produced by our factory is divided into three types according to the material: carbon steel tubular condenser, stainless steel tubular condenser and carbon steel and stainless steel mixed tubular condenser. According to the form, it is divided into fixed tubesheet type, floating head type and U-tube heat exchanger. According to the structure, it is divided into single tube, double tube and multi-tube. Heat transfer area is 0.5-500 m2, which can be customized according to user's needs.

| Diameter (mm) | Number of tubes | Tube quantity | Heat exchanger Nominal value/calculated value | Flow speed :0.5m/sec Flow: m/hr | Pressure | |||||

| Tube length (m) | φ25×2.5 | |||||||||

| 1500 | 2000 | 3000 | 4000 | 6000 | φ25×2 | |||||

| 159 | 1 | 14 | 1.51.62 | 22.17 | 33.27 | 0.0044/ 0.0049 | 7.92/8.82 | 0.25 | ||

| 219 | 1 | 26 | 3/3.00 | 4/4.02 | 6/6.06 | 8/8.1 | 0.0082/0.0090 | 14.76/16.20 | 0.6 | |

| 2 | 26 | 3/3.00 | 4/4.02 | 6/6.06 | 8/8.81 | 0.0041/0.0045 | 7.38/8.01 | 1.0 | ||

| 273 | 1 | 44 | 5/5.08 | 7/5.18 | 10/10.26 | 14/13.72 | 21/20.63 | 0.0138/0.0152 | 24.84/27.36 | 1.6 |

| 2 | 40 | 5/4.62 | 6/6.19 | 9/9.33 | 12/12.47 | 19/18.76 | 0.0063/0.0069 | 11.24/12.42 | 2.5 | |

| 325 | 1 | 60 | 7/6.93 | 9/9.28 | 14/14.00 | 19/18.71 | 28/28.13 | 0.0188/0.0208 | 33.84/37.44 | 0.6 |

| 2 | 56 | 6/6.47 | 9/8.66 | 13/13.05 | 17/17.46 | 36/26.26 | 0.0088/0.0097 | 15.84/17.46 | 1.0 | |

| 400 | 1 | 119 | 14/13.47 | 18/18.41 | 28/27.76 | 37/37.10 | 55/55.8 | 0.0374/0.0412 | 67.32/74.16 | 1.6 |

| 2 | 110 | 13/12.70 | 17/17.02 | 26/25.66 | 34/34.20 | 50/51.58 | 0.0173/0.0190 | 31.14/34.20 | 2.5 | |

| 500 | 1 | 185 | 45/4.15 | 55/57.68 | 85/86.74 | 0.0581/0.0641 | 104.58/115.38 | |||

| 2 | 180 | 40/41.99 | 55/57.68 | 85/86.74 | 0.0283/0.0312 | 50.94/56.16 | ||||

| 600 | 1 | 269 | 60/62.7 | 85/83.88 | 125/126.13 | 0.0845/0.0932 | 152.10/167.76 | |||

| 2 | 266 | 60/32.05 | 80/82.94 | 125/14.72 | 0.0418/0.0461 | 75.24/83.98 | ||||

| 700 | 1 | 379 | 90/88.41 | 120/118.17 | 175/177.71 | 0.0091/0.1313 | 214.38/236.34 | |||

| 2 | 358 | 85/83.51 | 110/111.62 | 165/167.85 | 0.0562/0.0620 | 101.16/111.60 | ||||

| 800 | 1 | 511 | 120/119.20 | 160/159.16 | 240/239.60 | 0.1605/0.1770 | 288.90/318.60 | |||

| 2 | 488 | 115/113.83 | 150/152.16 | 230/228.81 | 0.0767/0.0845 | 138.06/152.10 | ||||

| 900 | 1 | 649 | 150/151.39 | 200/202.36 | 305/304.3 | 0.2039/0.2248 | 367.02/404.46 | |||

| 2 | 630 | 145/146.96 | 195/196.44 | 295/295.40 | 0.0990/0.1091 | 178.20/196.38 | ||||

| 1000 | 1 | 805 | 185/187.78 | 250/251.00 | 375/377.45 | 0.2529/0.2788 | 455.22/501.74 | |||

| 2 | 792 | 185/184.75 | 245/246.95 | 370/371.36 | 0.1244/0.1374 | 223.92/246.96 | ||||

Company Features

1. Guangdong Jinzong Machinery Co., Ltd. has accumulated a good reputation and image in chemical machine market.

2. Guangdong Jinzong Machinery Co., Ltd. has introduced large glass-lined reactor production machines to guarantee delivery time and produce different lab reactor .

3. Guangdong Jinzong Machinery Co., Ltd. assures problems of customers are problems of ours and we will surely help. Check now! With the management philosophy of automatic control system , Jinzong Machinery provides professional shopping experience. Check now! Guangdong Jinzong Machinery Co., Ltd.'s main force is to push acylic resin reactor . Check now!

Xinxiang Dongzhen Machinery ,located in high tech Development Zone of Xinxiang City, which is an enterprise integrated scientific researching,device producing and product marketing. We mainly produces DZ series vibrating screen,linear vibration sieve,test sieve,vibration conveyor,vibration feeder and other handling equipment.

Certifications

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)