Multi functional extraction and concentration plant

*Features:

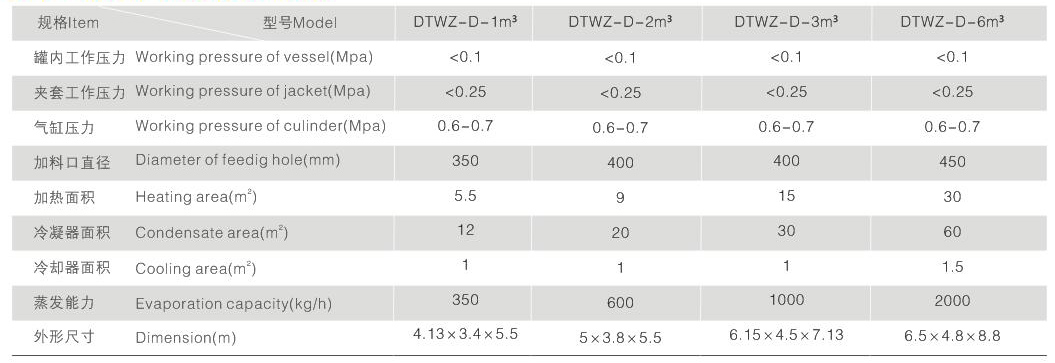

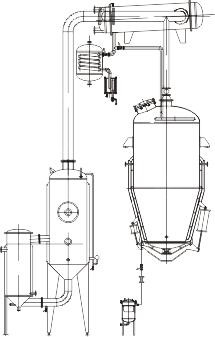

1. The plant is mainly composed of extraction tank, external circulation single effect concentrator and other auxiliary equipment, with compact structure and convenient operation, which integrates extraction, concentration and solvent recovery.

2. The equipment has multi functional, suitable for water extraction and alcohol / ethanol extraction, can be extracted under atmospheric pressure and negative pressure, and can recover volatile oil. Equipped with vacuum converter and control box, it is easy to operate, and can realize the process requirements of normal temperature extraction and low temperature concentration, normal temperature extraction and concentration, etc.

3. The oil-water separator is composed of two glass cylinders, so that the oil-water separation time is longer and the separation effect is better. It is made of glass for easy observation.

4. High gravity flow method is used for concentration. Evaporated distilled water is returned to the extraction tank to increase the concentration difference between solvent and medicinal materials, and improve the extraction efficiency. The whole reflux extraction and concentration process takes about 4-6 hours. Reduce the loss of steam and solvent, shorten the operation time.

5. The recovered high-efficiency solvent is directly sent to the alcohol preparation tank and used as the solvent in the alcohol precipitation tank or extraction tank

*MAIN COMPOSITION of multi-functional extraction and concentration plant:

The plant is mainly composed of extraction tank, external circulation single effect concentrator and other auxiliary equipment.

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist