Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

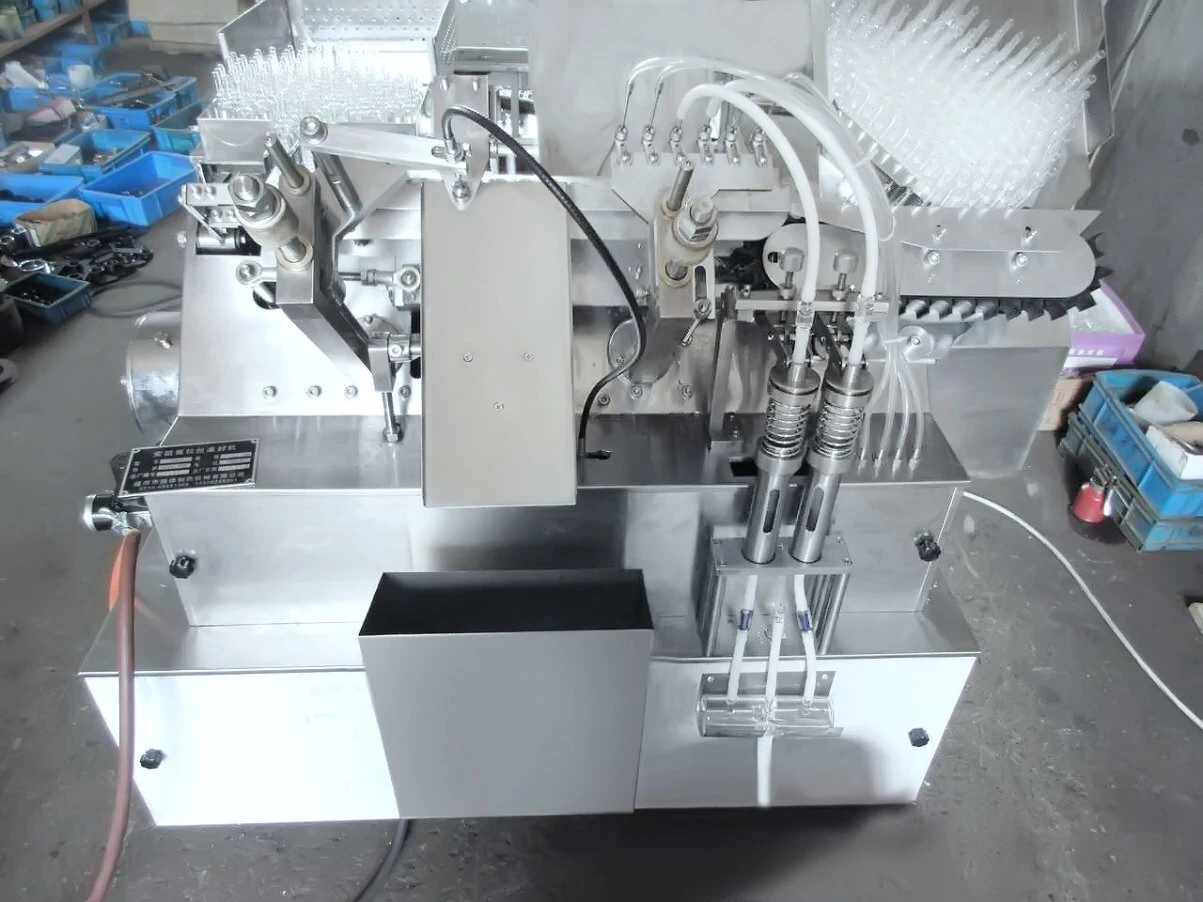

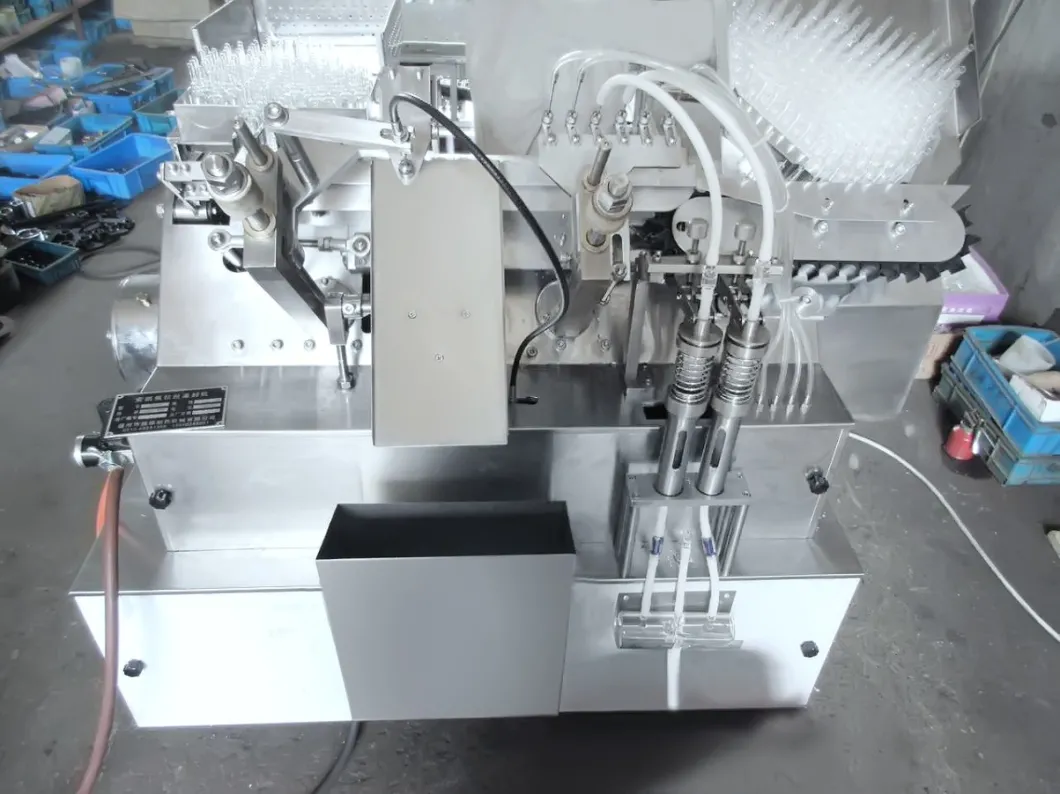

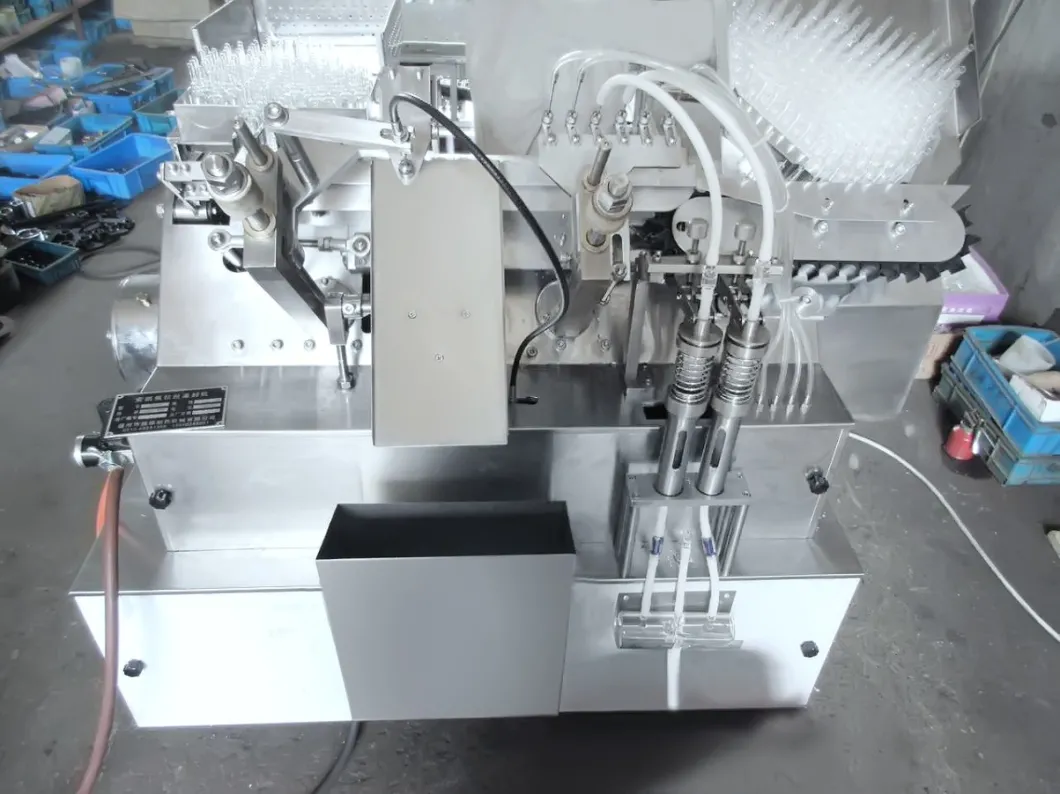

Ampoule Blow-Fill-Seal Filling and Sealing Machine

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

| Material Type | Liquid | Packaging | Bottles |

| Packaging Material | Plastic, Glass | Trademark | JINZONG |

| Transport Package | Wooden Case | Specification | SUS304, 316L |

| Origin | Guangdong | HS Code | 8422303090 |

Ampoule blow-fill-seal Filling and Sealing Machine

The ampoule filling and sealing machine is an upgraded product of the injection ampoule filling and sealing machine. The capacity of this machine have been increased three times of the single-needle ampoule filling and sealing machine.

This machine adopts a rectangular bottle feeding method, fast bottle feeding moving and bottle slow down on the moving tooth plate, which makes the bottle have enough time to stay on the fixed tooth plate.

The clutch device is installed under the bottle feeding bucket, so that the ampoules can be stopped in the bucket.

ampoule filling and sealing machine is suitable to fill and seal ampoule bottles for pharmaceutical, chemical industry. The piston metering pump is adopted to fill ampoule bottle, and no bottles no filling, gas can be used for gas, liquefied natural gas, liquefied petroleum gas. This machine is a double needle type, compact structure, stable operation, reliable operation, convenient operation, complete functions.

Technical parameter

Filling range: 1-20ml

Capacity: 3000-3600 ampoules/h

Gas type: Coal gas, liquefied petroleum gas

"No Ampoule - No Filling " system

Possibility of nitrogen gas flushing before, during and after filling.

All contact parts are made of SUS316L, and other parts non-contact parts made from SUS304.

Meet for GMP standard

Ampoule neck centering during gas flushing and filling operations. 200L/H

Supply power: 380V/220V 50Hz

Power: 0.37KW

Dimensions: 1300×700×1400mm

Weight: 120KG

The ampoule filling and sealing machine is an upgraded product of the injection ampoule filling and sealing machine. The capacity of this machine have been increased three times of the single-needle ampoule filling and sealing machine.

This machine adopts a rectangular bottle feeding method, fast bottle feeding moving and bottle slow down on the moving tooth plate, which makes the bottle have enough time to stay on the fixed tooth plate.

The clutch device is installed under the bottle feeding bucket, so that the ampoules can be stopped in the bucket.

ampoule filling and sealing machine is suitable to fill and seal ampoule bottles for pharmaceutical, chemical industry. The piston metering pump is adopted to fill ampoule bottle, and no bottles no filling, gas can be used for gas, liquefied natural gas, liquefied petroleum gas. This machine is a double needle type, compact structure, stable operation, reliable operation, convenient operation, complete functions.

Technical parameter

Filling range: 1-20ml

Capacity: 3000-3600 ampoules/h

Gas type: Coal gas, liquefied petroleum gas

"No Ampoule - No Filling " system

Possibility of nitrogen gas flushing before, during and after filling.

All contact parts are made of SUS316L, and other parts non-contact parts made from SUS304.

Meet for GMP standard

Ampoule neck centering during gas flushing and filling operations. 200L/H

Supply power: 380V/220V 50Hz

Power: 0.37KW

Dimensions: 1300×700×1400mm

Weight: 120KG

Under organized guidance, a team of chemical reactor specialists on chemical reactor was gathered at Guangdong Jinzong Machinery Co., Ltd..

Guangdong Jinzong Machinery Co., Ltd. has stable production bases and manufacture center for our mechanical equipment.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. www.jinzongmachinery.com| Sitemap Privacy Policy