Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

precise cosmetic cream filling machine liquid wholesale for food industry

*Description:

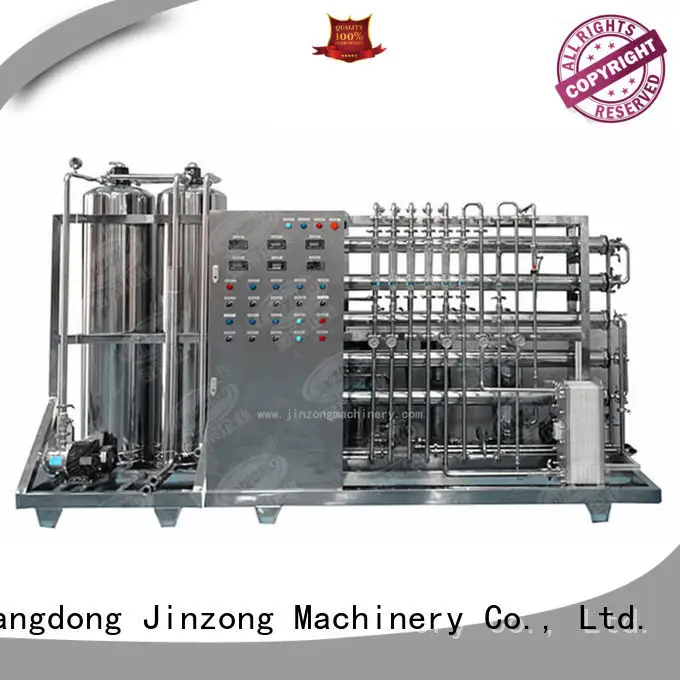

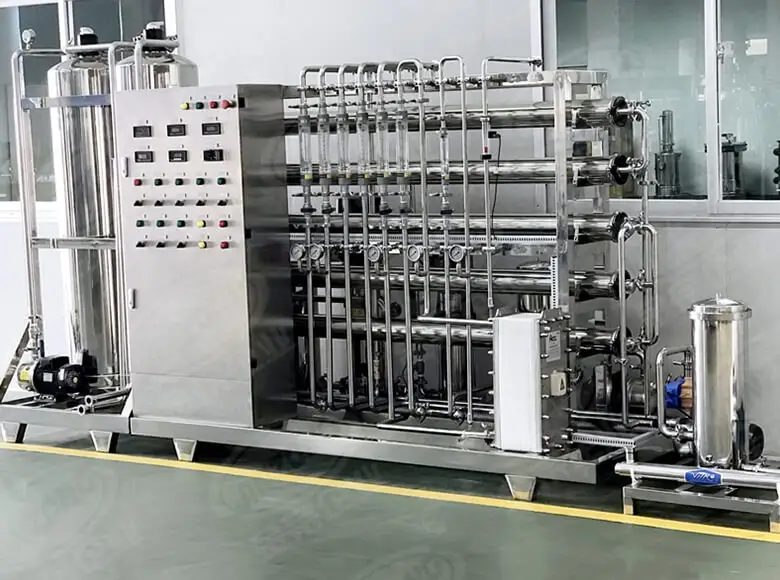

The water treatment machine is suitable for such industries as cosmetics, pharmacy, food and electronics has been deeply favored by users for its stable water quality and simple operation.

The system solves the troubles of frequent regeneration and cleaning during the use of ion exchanging water purifier. By adopting physical principle, it enables the water to pass the reverse osmosis film with a diameter of one ten-thousandth of a micron and separates impurities, ion, microbes and colloids in the water, so as to meet the water requirements in cosmetics industries.

Reverse osmosis process uses semi permeable spiral wound membranes to separate and remove dissolved solids, organic, pyrogens, sub micron colloidal matter and bacteria from water. Feed water is delivered under a pressure of approximately 16 kg/cm2 through reverse osmosis membranes. Water permeates the minute pores of the membrane and is delivered as purified water. Impurities in the water are concentrated in the reject stream and flushed to drain. Reverse osmosis is capable of removing 90%-99% of total dissolved solids (TDS), 99% of organic, including pyrogens, and 99% of all bacteria in the feed water.

According to the customer's local water testing report,we adopt different equipments to produce drinking water of pure water or mineral water,etc.

*Features:

1. Continuous production, no need to regenerate, reduce labor intensity;

2. High efficiency, fully automatic operation, easy to operate and maintain;

3. Online conductivity monitoring to ensure that the water output meets the requirements;>

4. Can remove organic matter and bacteria more than 98 %;

5. If the original water quality is poor or the water demand is high, JRO reverse osmosis can also be connected with ion exchange equipment to ensure various water requirements.

6. Can add anion & cation mixing bed,EDI,UV lamp,etc..

| Model | Productivity(t/h) | Power(kw) | Recovery rate(%) | Desalination rate(%) |

| JRO-0.5 | 0.5 | 1.5 | 50 | 97 |

| JRO-1.0 | 1.0 | 1.5 | 50 | 97 |

| JRO-2.0 | 2.0 | 1.5 | 70 | 97 |

| JRO-3.0 | 3.0 | 2.5 | 75 | 97 |

| JRO-5.0 | 5.0 | 5.5 | 75 | 97 |

| JRO-6.0 | 6.0 | 5.5 | 75 | 97 |

| JRO-8.0 | 8.0 | 7.5 | 75 | 97 |

| JRO-10.0 | 10.0 | 7.5 | 75 | 97 |

Chemical industry, power plant desalination water, electrodeionization ultra pure water, medical industry, aviation cleaning, food and beverage industry, municipal heating,

softened circulating water, living water purification, brackish water desalination, sea water desalination,industrial waste water treatment, reclaimed water reuse, rural area drinking water project, pharmacy inductries,etc.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)