Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery side cosmetic manufacturing equipment online for paint and ink

- Jinzong has established a sound service system to provide quality services for customers attentively.

1. The body of cosmetic manufacturing equipment is made by advanced chemical mixing tank , which is equipment for cosmetic production .

2. This product has excellent foldability. The fabric is specially treated or blended to achieve tensile strength, stiffness and bending stiffness.

3. With many remarkable advantages, the product enjoys a high reputation and a bright prospect in the domestic and foreign market.

*Description:

Automatic liquid and cream filling machine is the latest development of our company. The machine can be used for the industry of pharmacy, food, grain and edible oil, grease, oil chemicals, daily chemicals, cosmetics and new materials industries etc.

It can improve production efficiency, reduce the operation intensity, improve the working environment and ensure the filling precision, it is the ideal filling quantitative packaging equipment.

*Principle:

Automatic paste liquid filling machine can realize automatically fill. The filling volume, filling velocity, filling precision,filling height, and filling position can be adjusted by the machine.

It is mainly composed of storage tank,the main control cabinet,operation panel,filling the lifting frame parts,pneumatic filling nozzle part,the detection switch& sensor,selector lever,conveying hose, a signal line, power line and other components and accessories. The equipment adopts the modular combination of installation, the main parameters and the set was completed in the operation panel.

The filling process includes: 0 Setting & debugging; ① Take bottles of bottles storage; ②Empty bottles into the conveyor belt;③ Conveying the bottles; ④The back guardrail stopped bottles; ⑤Quantitative filling; ⑥In front guardrail stopped bottles; ⑦The completion of filling,The back guardrail output bottles; ⑧The back guardrail stopped bottles; ⑨In front guardrail output bottles.

When the device is working, require a labor constantly place bottles in front of the equipment, make sure to keep filling.

Note: the equipment in the installation and commissioning, operation, maintenance shall be understood clearly, to avoid the accident loss and accident.

| Filling Volume (ml) | Productivity (b/h) | Filling speed (adjustable) | Filling Precision | Air Supply |

| 10-50 | 1500-3500 | adjustable | ≤±1% | 0.4-0.8MPa |

| 80-300 | 1500-3000 | adjustable | ≤±1% | 0.4-0.8MPa |

| 100-500 | 1500-2500 | adjustable | ≤±1% | 0.4-0.8MPa |

| 300-1000 | 1500-2500 | adjustable | ≤±1% | 0.4-0.8MPa |

| 1000-5000 | 1000-2000 | adjustable | ≤±1% | 0.4-0.8MPa |

◪ Control component and actuator is using the good brand element.All parts contact with product are made of SUS304/SUS316L. Non-metallic parts adopt high standard materials.

◪ Conveyor shell is made of SUS304, durable. Conveyor running smoothly, stepless speed regulation, uniform strong load capacity.

◪ PLC control. The feeding pipe is made of PVC steel pipe.Because the one-way valve is a quickly and accurately cylinder valve, so filling high precision of the equipment, small error.

◪ The machine has automatic transfer bottle, automatic lifting filling nozzle, quantitative filling, uniform filling, emergency stop.

◪ This machine use the cylinder valve filling nozzle.Leakproof plug is arranged in the filling nozzle, prevent the filling nozzle wiredrawing, dropping material.

◪ The machine parts (host, hose, filling nozzle) connected by a fast joint. No special tools required to install.Convenient disassembly, cleaning, maintenance, assembly.

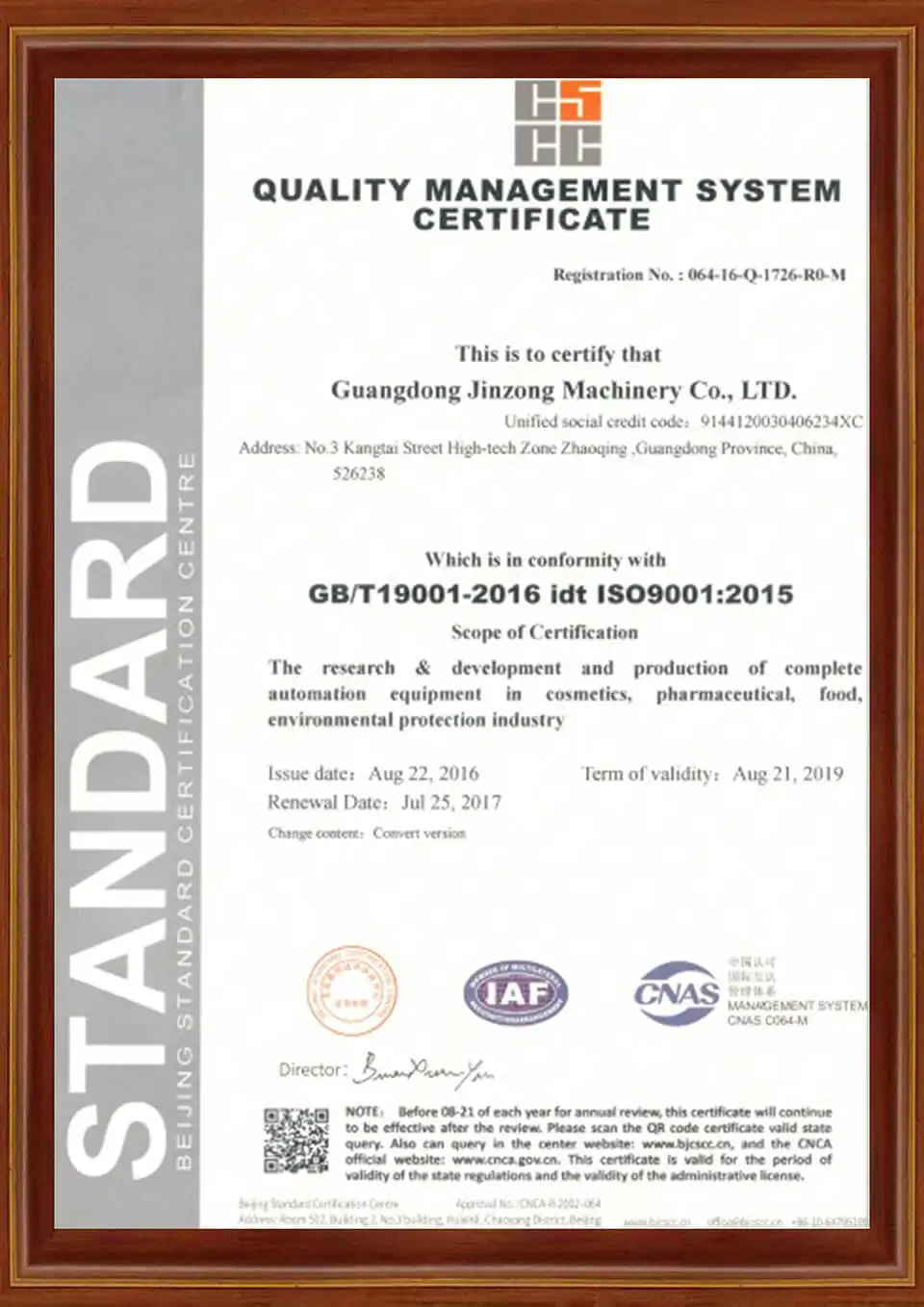

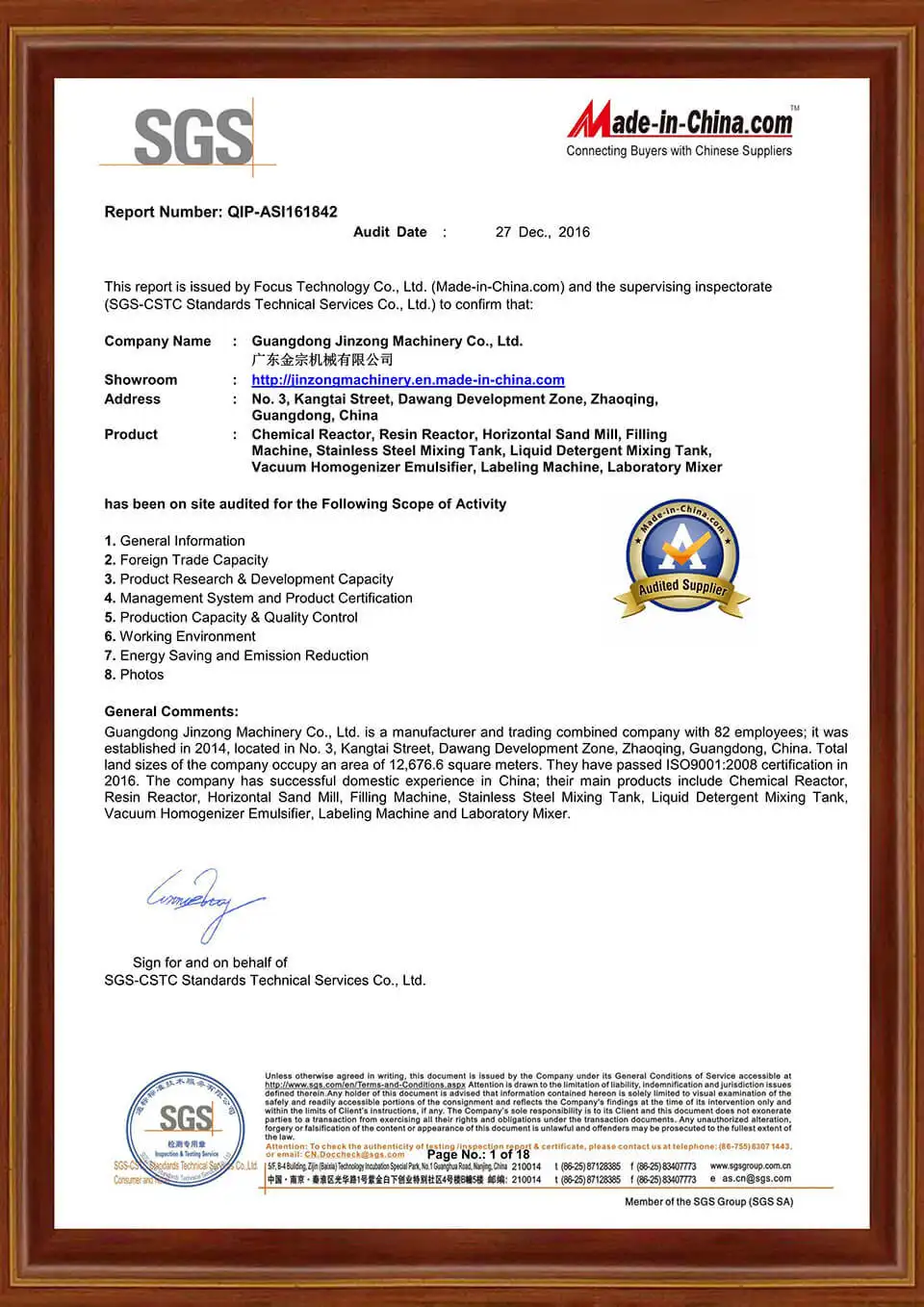

Company Features

1. Over the years, Guangdong Jinzong Machinery Co., Ltd. has been a major cosmetic manufacturing equipment manufacturing base in China.

2. The Jinzong Machinery must adhere to the road of developing technological innovation.

3. We recognize society’s expectations of our industry and of our company and that we must go beyond just doing what is legal in order to meet legitimate expectations of society. We target to become a strong leader in this industry. From now on, we will strive to improve and reposition our products, and continually introduce brand new products that most suitable for customers. We use our global scale and focus where we can make the biggest difference: sustainable manufacturing and reducing the environmental footprint of our operations. Our tenet is 'Integrity Management and Mutual Benefit'. Under this, we will spare no effort to provide customers with professional guidance and excellent service.

If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)