Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Ceramic Horizontal Sand Mill

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

| Model NO. | JHN | Working Style | High-speed universal |

| Disc Diameter | Special Design | Variable Speed | With Variable Speed |

| Milling Class | Nano | Trademark | Jinzong Machine |

| Transport Package | Durable Wooden Case | Specification | 0.5L, 6L, 10L, 25L, 62L, 121L |

| Origin | Guangdong, China | HS Code | 8479820090 |

Ceramic Horizontal Sand Mill

*Main features

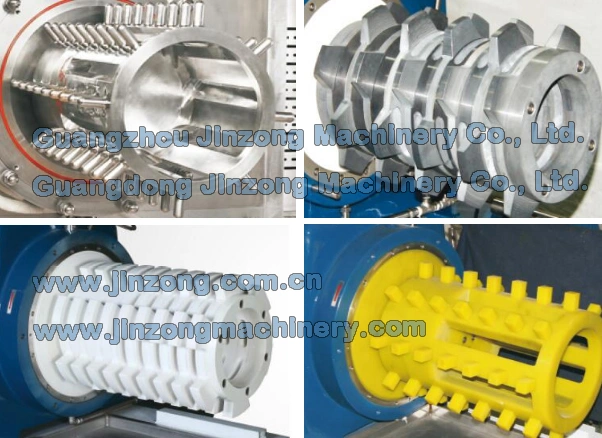

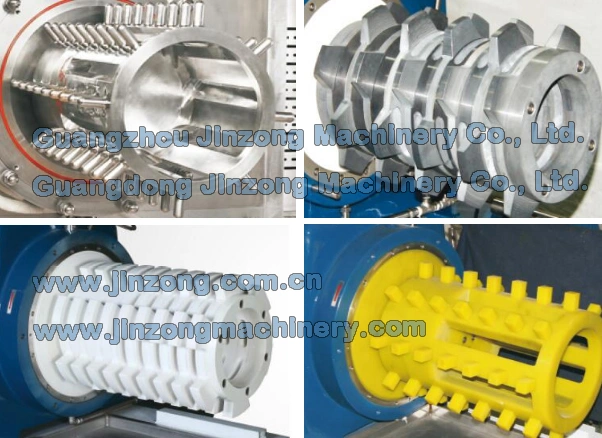

Jinozng Horizontal Nanomills system combines the well-known special separation system designed by Jinzong. This agitator bead mill was specifically developed by Jinzong engineers for high energy, high flow, multiple pass and specifically circulation operation grinding to achieve very narrow submicron particle size distributions with excellent repeatability.

Mainly designed for the middle and small lot manufacture of middle and high class product.

Using solvent discharging valve gear in the small mill barrel can make no material draffy remain in the barrel consequently reduce the waste.

This machine is very economic for middle and small manufacture and can meet more requirement of customer.

The high precision separation device can use those mill beads which has small diameter and get high output..

*Application:

*Printing inks

*Filters

*Packing inks

*Coil coatings

*Special coatings

*Special chemicals

*Chemical fiber coatings

*Agriculture chemicals

*Minerals

*Non ferrous metals

*Cosmetics

*Gravure inks

*Offset inks

*Paints

*Paper coatings

*Hard Metals

*Advantage:

The rotor-slotted pipe separation system of JHN peg mill, provides high energy input in comparison to other mills with the same grinding chamber volume, which guarantees high efficient grinding process and high product throughput capacity. The slotted pipe is within the agitator shaft and there is almost no grinding beads around the slotted pipe since the centrifugal force moves beads out of the agitator shaft. The product exit is removed to close to lower part of the flange to avoid possible block of the product because of the slurry dposition.

Rotary dynamic separation device can be added at the product outlet to suit to the smallest beads with size down to 0.5mm and to grind the products with flake-shape..

*Technical Parameter

Note: In case of inconformity of the data in the table due to technical improvement or customization, the real object shall prevail.

*Other paint production equpment:

*After-sales service:

1> one year from date of delivery, if any spare parts be broken within warranty and not caused by improperly operation, we would offer the new parts for free.

2> Provide professional after-sales service engineers to abroad installation and debugging.

*ONE-STOP SERVICES

According to market and customer demands, our company is continuously researching, developing, upgrading and improving various products, striving to build the firs "one-stop" type cosmetic machinery shopping with machinery & equipment, cosmetic raw material, packing materials, technical consultation and other services

*Providing technical support in the aspects of field commissioning and running of the products sold.

*Field failure diagnosis and maintenance.

*Providing spare parts and fittings, maintenance and servicing plans.

*Choosing Jinzong Machinery is choosing professional technical support and good after-sales service.

*About us:

Guangzhou / Guangdong Jinzong Machinery Co., Ltd. is a professional manufacturer of cosmetic,chemical, biological & pharmaceutical machinery and equipment more than 20 years .

Jinzong Machinery is a technology innovative enterprise focusing on machinery design, manufacturing and system integration.

Product lines range from:

1> Cosmetic Machinery: water treatment ,vacuum emulsifying machine,liquid detergent mixing machine,storage tank,solid soap making machine,perfume making machine, color paste mill, filling machine etc.

2> Chemical Machinery: reactor, mixing equipment, separation equipment, storage tank, disperser, sand mill etc.

3> Biological and Pharmaceutical Machinery: vacuum ointment machine, fermentation tank, sanitary stainless reactor,alcohol deposition can, collocation tank etc.

*Our strength

1. More than 20 years extensive experience in the machinery manufacturing in Cosmetic and cheimical biological & pharmaceutical industry.

2. Quality, 80% materials and components are purchased from 3M, ABB, Siemens, Panasonic, Schneider. Up to now, all core machinery are with CE Certificate. We carry out products designing, manufacturing, assembling and detection fully in accordance with ISO9001-2008 Quality Management System issued by Swiss SGS Company.

3. Good reputation in industry. Many years are awarded "defend the contract heavy credit enterprise"

4.Have a Professional after-sales service engineering team.

5.Large scale plant. Currently, we have 2 processing bases, Zhaoqing factory, covering a total area of more than 17,000 square meters,and Shaoguan factory,covering a total area of more than 30,000 square meters. There are more than 160 sets of processing machinery including large vertical lathe, 5-axis horizontal machining center, large planer type milling machine, automatic polishing machines etc. With the help of our strong processing capacity, we produce more than 1000 sets of equipment every year

*Main features

Jinozng Horizontal Nanomills system combines the well-known special separation system designed by Jinzong. This agitator bead mill was specifically developed by Jinzong engineers for high energy, high flow, multiple pass and specifically circulation operation grinding to achieve very narrow submicron particle size distributions with excellent repeatability.

Mainly designed for the middle and small lot manufacture of middle and high class product.

Using solvent discharging valve gear in the small mill barrel can make no material draffy remain in the barrel consequently reduce the waste.

This machine is very economic for middle and small manufacture and can meet more requirement of customer.

The high precision separation device can use those mill beads which has small diameter and get high output..

*Application:

*Printing inks

*Filters

*Packing inks

*Coil coatings

*Special coatings

*Special chemicals

*Chemical fiber coatings

*Agriculture chemicals

*Minerals

*Non ferrous metals

*Cosmetics

*Gravure inks

*Offset inks

*Paints

*Paper coatings

*Hard Metals

*Advantage:

The rotor-slotted pipe separation system of JHN peg mill, provides high energy input in comparison to other mills with the same grinding chamber volume, which guarantees high efficient grinding process and high product throughput capacity. The slotted pipe is within the agitator shaft and there is almost no grinding beads around the slotted pipe since the centrifugal force moves beads out of the agitator shaft. The product exit is removed to close to lower part of the flange to avoid possible block of the product because of the slurry dposition.

Rotary dynamic separation device can be added at the product outlet to suit to the smallest beads with size down to 0.5mm and to grind the products with flake-shape..

*Technical Parameter

| Model | JHN0.5 | JHN6 | JHN10 | JHN25 | JHN60 | JHN150 |

| L | 0.5 | 6 | 10 | 25 | 62 | 151 |

| Cylinder volume | ||||||

| L | 3-10 | 20-200 | 100-1000 | 500-2000 | ≥2000 | ≥4000 |

| Batch processing | ||||||

| kw | 4-5.5 | 13.5-15 | 17.5-22 | 37-45 | 70-90 | 160 |

| Power | ||||||

| rpm | 600-2500 | 600-1800 | 700-1300 | 700-1000 | 500-600 | 200-480 |

| Speed | ||||||

| kg/h | 20-59 | 100-500 | 250-1000 | 500-2500 | 1000-6000 | 2000-15000 |

| Efficiency | ||||||

| mm | 520 | 1150 | 1150 | 1850 | 2200 | 2900 |

| Length | ||||||

| mm | 250 | 700 | 700 | 960 | 1000 | 1250 |

| Width | ||||||

| mm | 1000 | 1750 | 1750 | 1800 | 2250 | 2650 |

| Highly | ||||||

| kg | 225 | 650 | 1350 | 2000 | 3500 | 6900 |

| Weight |

*Other paint production equpment:

*After-sales service:

1> one year from date of delivery, if any spare parts be broken within warranty and not caused by improperly operation, we would offer the new parts for free.

2> Provide professional after-sales service engineers to abroad installation and debugging.

*ONE-STOP SERVICES

According to market and customer demands, our company is continuously researching, developing, upgrading and improving various products, striving to build the firs "one-stop" type cosmetic machinery shopping with machinery & equipment, cosmetic raw material, packing materials, technical consultation and other services

*Providing technical support in the aspects of field commissioning and running of the products sold.

*Field failure diagnosis and maintenance.

*Providing spare parts and fittings, maintenance and servicing plans.

*Choosing Jinzong Machinery is choosing professional technical support and good after-sales service.

*About us:

Guangzhou / Guangdong Jinzong Machinery Co., Ltd. is a professional manufacturer of cosmetic,chemical, biological & pharmaceutical machinery and equipment more than 20 years .

Jinzong Machinery is a technology innovative enterprise focusing on machinery design, manufacturing and system integration.

Product lines range from:

1> Cosmetic Machinery: water treatment ,vacuum emulsifying machine,liquid detergent mixing machine,storage tank,solid soap making machine,perfume making machine, color paste mill, filling machine etc.

2> Chemical Machinery: reactor, mixing equipment, separation equipment, storage tank, disperser, sand mill etc.

3> Biological and Pharmaceutical Machinery: vacuum ointment machine, fermentation tank, sanitary stainless reactor,alcohol deposition can, collocation tank etc.

*Our strength

1. More than 20 years extensive experience in the machinery manufacturing in Cosmetic and cheimical biological & pharmaceutical industry.

2. Quality, 80% materials and components are purchased from 3M, ABB, Siemens, Panasonic, Schneider. Up to now, all core machinery are with CE Certificate. We carry out products designing, manufacturing, assembling and detection fully in accordance with ISO9001-2008 Quality Management System issued by Swiss SGS Company.

3. Good reputation in industry. Many years are awarded "defend the contract heavy credit enterprise"

4.Have a Professional after-sales service engineering team.

5.Large scale plant. Currently, we have 2 processing bases, Zhaoqing factory, covering a total area of more than 17,000 square meters,and Shaoguan factory,covering a total area of more than 30,000 square meters. There are more than 160 sets of processing machinery including large vertical lathe, 5-axis horizontal machining center, large planer type milling machine, automatic polishing machines etc. With the help of our strong processing capacity, we produce more than 1000 sets of equipment every year

Guangdong Jinzong Machinery Co., Ltd. is greatly willing to providing free samples for mechanical equipment. The product is very easy to maintain.

Jinzong Machinery is well known as a reliable company which provides professional service. The product is very easy to maintain.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. www.jinzongmachinery.com| Sitemap Privacy Policy