Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Active Pharmaceutical Ingredients intermediate manufacturing plant

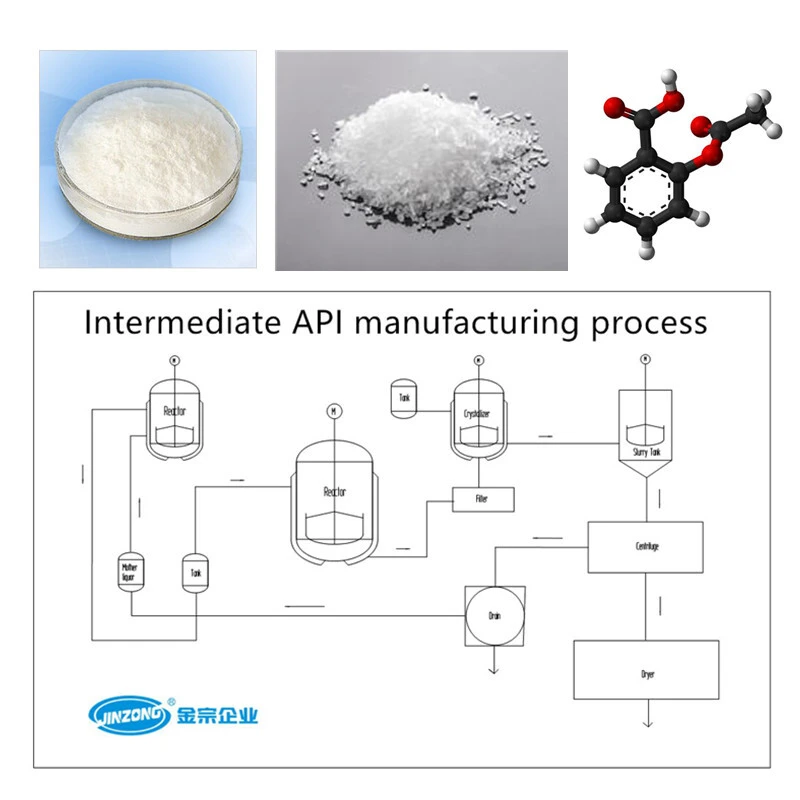

Active Pharmaceutical Ingredient (API) is the biologically active component of a drug product (tablet, capsule, cream, injectable) that produces the intended effects.Active pharmaceutical ingredient means any substance that is intended for incorporation into a finished drug product and is intended to furnish pharmacological activity or other direct effect in the diagnosis, cure, mitigation, treatment, or prevention of disease, or to affect the structure or any function of the body.The Active Pharmaceutical Ingredient (api processing equipment) manufacturing process is a series of related operations that result in the finished product. The major operations may include multi-step chemical synthesis, fermentation, purification, drying, milling, and labeling.

*API manufacturing process include:

Synthesis

Distillation

Extractions

Crystallization

Purification

Filtration

Drying

Milling

Packing

*MAIN COMPOSITION of API manufacturing plant:

API manufacturing plant consist the following equipments and accessories: reactors, mother liquor, storage tank, condenser, crystallizer, slurry tanks, filter, centrifuge machine, dryer, transfer pumps.

*Features:

◪ Design compliance with cGMP.

◪ Customized;

◪ Available model from pilot plant to large scale manufacturing plant;

There are many benefits of using API pharma machinery in the pharmaceutical industry.

Increased efficiency: API pharma machinery helps to automate processes within the pharmaceutical manufacturing process, allowing for faster and more efficient production processes.

Improved quality control: With the use of API pharma machinery, it is easier to maintain consistent product quality, which is a critical factor in the pharmaceutical industry.

Enhanced safety: API pharma machinery is designed with safety features that help to minimize the risk of accidents and injuries during the production process.

Reduced costs: API pharma machinery helps to reduce production costs by streamlining manufacturing processes and reducing wastage.

Faster time-to-market: The use of API pharma machinery can help pharmaceutical companies bring their products to market faster by speeding up the production process.

Scalability: Api processing equipment is designed to be scalable, allowing pharmaceutical companies to increase or decrease production capacity as needed.

Overall, the use of API pharma machinery offers many benefits that can help pharmaceutical companies improve efficiency, reduce costs, and enhance product quality and safety.

Why You Should Look For API pharmaceutical

There are many situations when you will benefit from knowing the APIs of medications you are taking.

Here are a few examples:

Duexis is a prescription medication used for treating arthritis. It contains ibuprofen (an anti-inflammatory) and famotidine (which protects against ulcers). Ibuprofen is also available in OTC form as Advil, Motrin, and as a generic. Famotidine is available in OTC form as Pepcid.

Robitussin DM is an OTC medication that's commonly used for treating symptoms of a common cold. This medication contains dextromethorphan, a cough suppressant, and guaifenesin, an expectorant. Guaifenesin is also the API In Mucinex, and dextromethorphan is the API In Delsym.

You could end up taking too much of any of these APIs if you aren't aware that they are available In different medications and brands. Furthermore, if a medication that you're taking isn't working or is causing side effects, then you can avoid jumping to the same API by a different name in a potentially futile attempt to try something that you think is different.

*API manufacturing plant:

In reality, raw materials are the base chemical compounds that are used to make an API. So, API manufacturers procure raw materials to produce this active component. The API is then supplied to the pharmaceutical manufacturers who use it to create drugs.Jinzong pharmaceutical ingredients manufacturers provides a full range of integrated solutions from R & D Lab test, pilot prodution to large scale production for the API industry, and provides pharmaceutical manufacturer with complete upstream and downstream of API process system design, which can meet the process requirements of different production lines of clients, including fermentation, extraction, chemical synthesis and related supporting systems, and assist customers to achieve high standard and high efficiency process flow.

Jinzong provides an intelligent API engineering integration solution for a pharmaceutical industry, covering the turnkey api project design, process optimization and automation control implementation. The pharma turnkey projects reflects the characteristics of Jinzong API technology "originated from process design and service process production", helps customers realize process optimization, improve production efficiency, and strive to build api production pipeline and automatic control demonstration project.

Questions? We can help! Contact us to discuss your project.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)