Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Condiment Baby Food Mayonnaise Production Line Mixing Machines and Equipment

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

| Warranty | 1 Year | Description | Vacuum Emulsifying Mixing Machine |

| Application | Cream, Ointment, Mayonnaise, Salad Dressing | Material of Contact Parts | SUS316L |

| Trademark | JINZONG | Transport Package | Plywood Case |

| Specification | SUS304, 316L | Origin | Guangdong |

| HS Code | 8419899090 |

condiment baby food Mayonnaise Production Line mixing machines and equipment

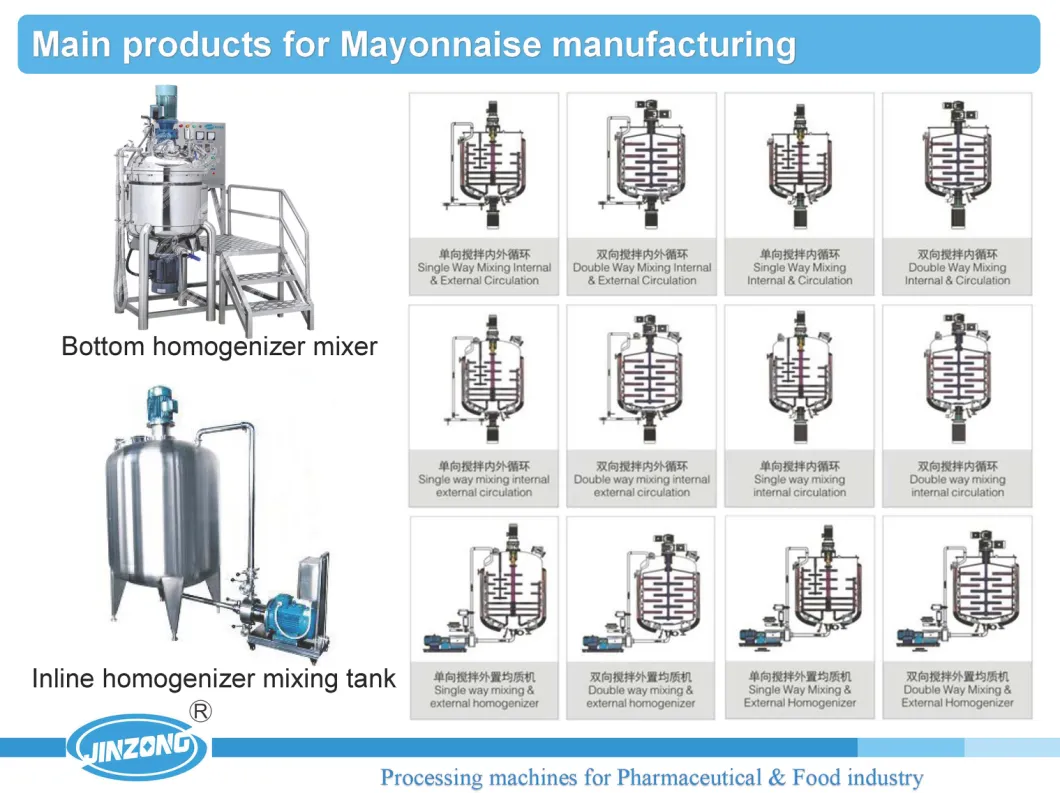

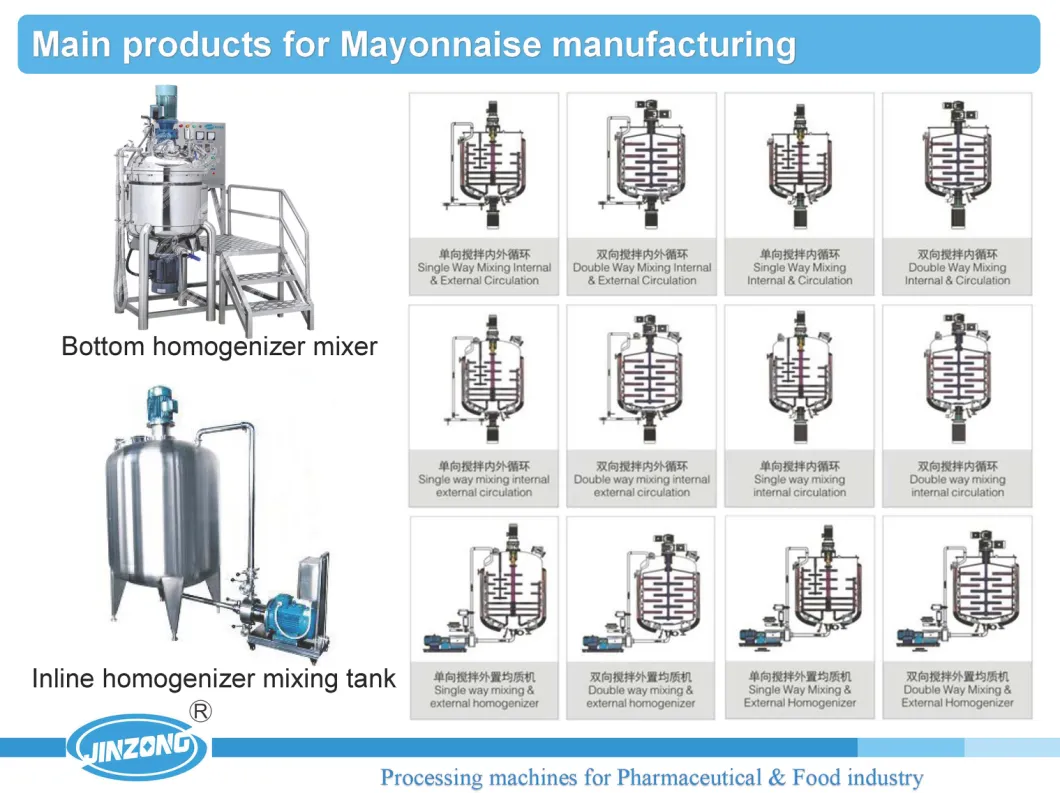

Jinzong mixing machine is the popular vacuum emulsifier homogenizer design in Asia and is suitable for making small to medium batches of mayonnaise, salad dressing,ointment, cream, Flavoring agent,Seasoning and emulsions.

Feature:

Working capacity from 10L to 5000L;

Suitable for mayonnaise, salad dressing,ointment, cream, Flavoring agent,Seasoning and emulsions of 10,000~50,000cps viscosity;

Internal emulsifying and homogenizing by top mounted batch homogenizer or bottom homogenizer;

All vessels are manufactured from S.S. 316 grade stainless steel sheets and are cGMP compliant construction.

The vessels are Jacketed, insulated, cladded and with suitable agitator assembly in each vessel.

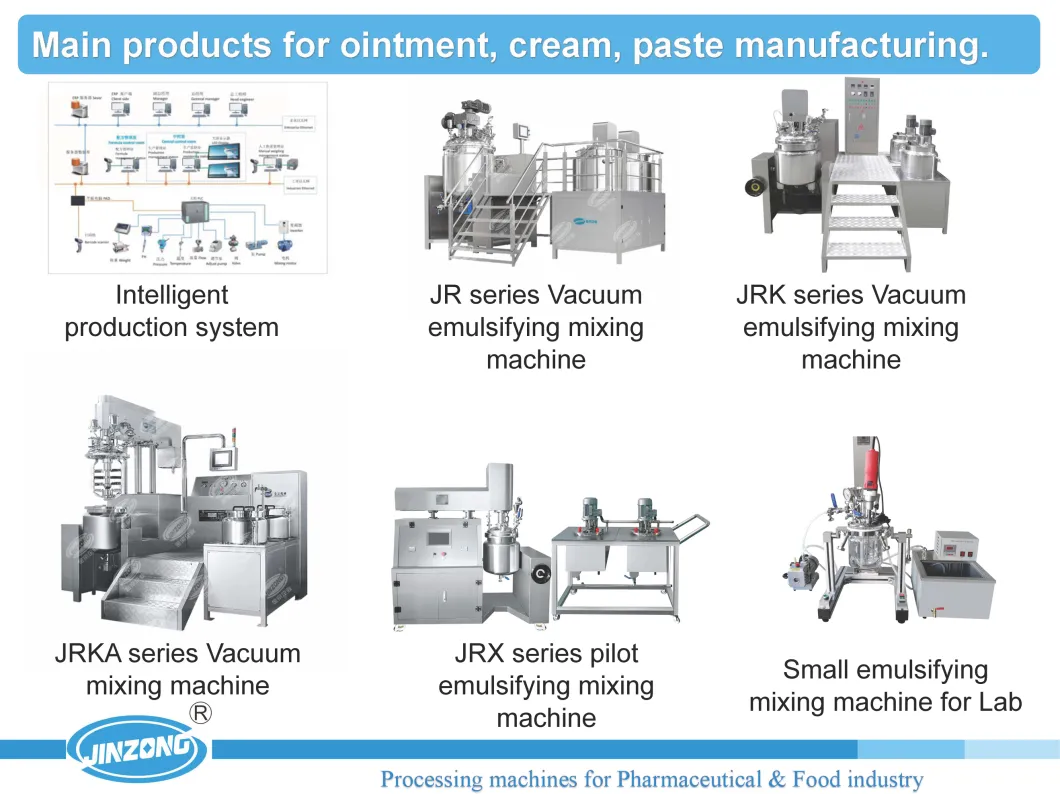

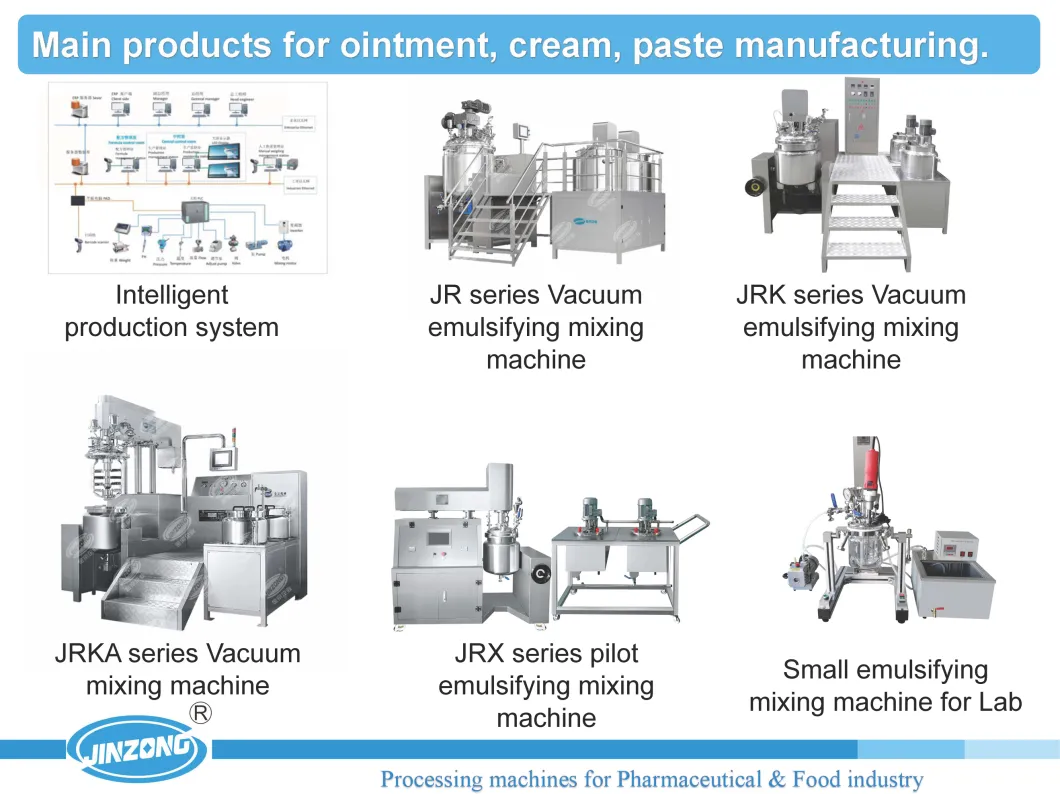

JR series Vacuum emulsifying mixing machine

JRK series Vacuum mixing machine

JRKA series Vacuum mixing machine

JRX series pilot emulsifying mixing machine

condiment baby food Mayonnaise Production Line mixing machines and equipment

Mixing tank structure

REQUEST FREE QUOTE

Contra mixing system of center agitator and wall scraper;

Outer frame agitator has triangle design for enhanced mixing;

Variable speed for homogenizer and agitators;

Oil hydraulic lifting system for easy cleaning and maintenance;

Double jackets for heating and cooling;

Different jacket designs available for steam and electric heating;

Complete process of mixing, dispersing, emulsifying, homogenizing, vacuum, heating and cooling in one unit;

Double temperature probes and controllers for electrical heating in main emulsification machine;

Vacuum system to take out the air bubbles during mixing and to transfer the ingredients;

Compressed air to discharge the finished cream;

Tilting system for discharging finished product and easy cleaning;

Multiple safety protection devices for vacuum, hydraulic pump and workers;

All contact parts are made of SS316L and mirror polished;

Spray ball is equipped to connect customer's CIP;

The specifications of the vacuum emulsification equipment comply with cGMP regulations;

Push buttons control panel for easy operation;

Power supply of 380V, 50Hz, 3 Phase;

Application

Cosmetics & Toiletries: cream, lotion, wax, mascara, gel, toothpaste;

Pharmaceuticals: ointment, dental composite, syrup, injection;

Food: mayonnaise, dressing, jam, butter, margarine, wasabi;

Chemicals: polyester, synthetic fiber, shoe cream;

Options

Fixed cover with bolts or welding to save budget;

Frame type slow agitator for oil pre-mixer;

Mettler-Toledo load cells;

Siemens PLC for automation of mixing, dispersing, emulsifying, homogenizing, vacuum, transferring, heating and cooling etc;

Flow meter automation for feeding liquid oil and water;

Pressure vessel design for different steam pressure;

SIP is available upon request;

Different power supply acceptable;

Project case:

Our mixer machine with wide range of food products designed as per demand our customer , Many our mixer for pickles, chutneys, ready to eat items, paste and sauces, frozen foods and spices , Garlic Chutney, Mint Chutney and Tamarind Chutney; Sweet Mango Chutney, Mango Ginger Chutney and Hot Mango Chutney , Mayonnaise Production Line/ machines and equipment.

Our Mixer and plant with vacuum emulsifying homogenizer mixer/ manufacturing plant and machine , Our production plant is use made with homogenizing mixer, Stainless Steel oil phase mixer, water phase mixer with vacuum system, hydraulic lifting line, Pump with materials circulation system, Product tank with heating and cooling system, temperature control system and electrical control panel etc.

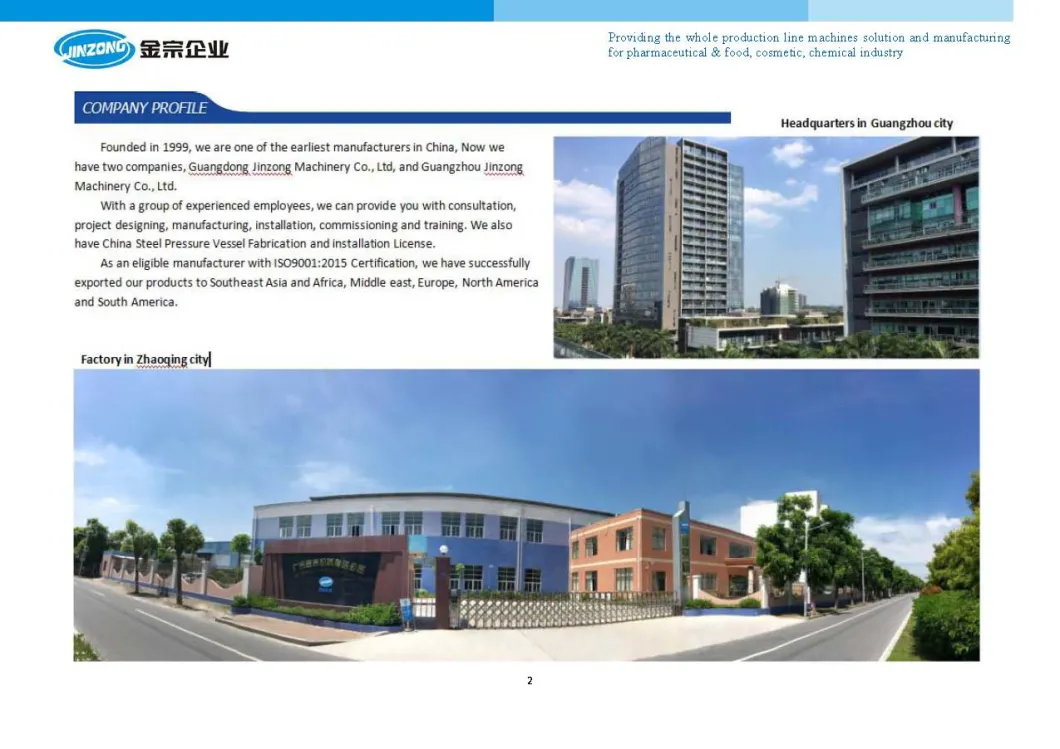

Guangdong Jinzong Machinery Co., Ltd. is a professional manufacturer of chemical, biological & pharmaceutical machinery and equipment more than 20 years .

Please do contact us should you have any inquiries about our product.

condiment baby food Mayonnaise Production Line mixing machines and equipment manufacturer

Jinzong mixing machine is the popular vacuum emulsifier homogenizer design in Asia and is suitable for making small to medium batches of mayonnaise, salad dressing,ointment, cream, Flavoring agent,Seasoning and emulsions.

Feature:

Working capacity from 10L to 5000L;

Suitable for mayonnaise, salad dressing,ointment, cream, Flavoring agent,Seasoning and emulsions of 10,000~50,000cps viscosity;

Internal emulsifying and homogenizing by top mounted batch homogenizer or bottom homogenizer;

All vessels are manufactured from S.S. 316 grade stainless steel sheets and are cGMP compliant construction.

The vessels are Jacketed, insulated, cladded and with suitable agitator assembly in each vessel.

JR series Vacuum emulsifying mixing machine

| Model | Volume of Main Tank (L) | Volume of Dissolving tank(L) | Dimension(mm) | total power(kw) | weitht(kg) |

| 100 | 130 | 70/100 | 2600*2500*2300 | 5.5 | 1200 |

| 200 | 260 | 120/190 | 2800*3000*2650 | 7.7 | 1600 |

| 300 | 375 | 150/260 | 2900*3000*2750 | 10.5 | 1900 |

| 500 | 620 | 300/460 | 3300*3550*3050 | 15 | 2500 |

| 1000 | 1250 | 620/900 | 4100*3900*3500 | 20.5 | 4000 |

| 2000 | 2600 | 1200/1500 | 4500*5200*4000 | 26 | 6000 |

| 3000 | 3800 | 1500/2400 | 4800*5700*4200 | 33 | 9000 |

| 5000 | 6500 | 2500/3600 | 5100*6400*4800 | 37 | |

| 10000 | 12500 | 5000/7000 | 52 |

JRK series Vacuum mixing machine

| Model | Volume of Main Tank (L) | Volume of Dissolving tank(L) | Dimension(mm) | total power(kw) | weitht(kg) |

| 50 | 75 | 45/65 | 2700*2300*1950-2650 | 9 | 1600 |

| 100 | 130 | 70/100 | 2900*2700*2050-2800 | 10 | 1800 |

| 200 | 260 | 120/190 | 3200*2900*2350-3300 | 13 | 2200 |

| 300 | 375 | 150/260 | 3350*3000*2550-3650 | 17 | 2500 |

| 500 | 620 | 300/460 | 3800*3400*2800-4050 | 25 | 3300 |

| 1000 | 1250 | 620/900 | 4150*4150*3700-5200 | 32 | 5000 |

JRKA series Vacuum mixing machine

| Model | Volume of Main Tank (L) | Volume of Dissolving tank(L) | Dimension(mm) | total power(kw) | weitht(kg) |

| 50 | 75 | 45/65 | 2700*2500*2000-2700 | 9 | 1600 |

| 100 | 130 | 70/100 | 2900*2500*2000-2800 | 10 | 1800 |

| 200 | 260 | 120/190 | 3200*3000*2400-3350 | 13 | 2200 |

| 300 | 375 | 150/260 | 3350*3100*2550-3650 | 17 | 2500 |

| 500 | 620 | 300/460 | 3800*3400*2850-4100 | 25 | 3300 |

| 1000 | 1250 | 620/900 | 4150*4150*3700-5200 | 32 | 5000 |

JRX series pilot emulsifying mixing machine

| Model | Volume of Main Tank (L) | Volume of Dissolving tank(L) | Main Tank Dimension(mm) | Dissolving Tank Dimension(mm) | Total Power (kw) |

| 5L | 1.2 | 3/3 | 1100*400*1250-1600 | 1000x600x800 | 6 |

| 10L | 13 | 6/10 | 1650*600*1800-2350 | 1200x600x800 | 8 |

| 20L | 26 | 12/16 | 1650*600*1800-2400 | 1200x600x800 | 10 |

| 30L | 37 | 18/25 | 1650*600*1800-2400 | 1200x600x800 | 15 |

| 50L | 60 | 30/40 | 1700*650*1900-2500 | 1200x600x900 | 19 |

Mixing tank structure

REQUEST FREE QUOTE

Contra mixing system of center agitator and wall scraper;

Outer frame agitator has triangle design for enhanced mixing;

Variable speed for homogenizer and agitators;

Oil hydraulic lifting system for easy cleaning and maintenance;

Double jackets for heating and cooling;

Different jacket designs available for steam and electric heating;

Complete process of mixing, dispersing, emulsifying, homogenizing, vacuum, heating and cooling in one unit;

Double temperature probes and controllers for electrical heating in main emulsification machine;

Vacuum system to take out the air bubbles during mixing and to transfer the ingredients;

Compressed air to discharge the finished cream;

Tilting system for discharging finished product and easy cleaning;

Multiple safety protection devices for vacuum, hydraulic pump and workers;

All contact parts are made of SS316L and mirror polished;

Spray ball is equipped to connect customer's CIP;

The specifications of the vacuum emulsification equipment comply with cGMP regulations;

Push buttons control panel for easy operation;

Power supply of 380V, 50Hz, 3 Phase;

Application

Cosmetics & Toiletries: cream, lotion, wax, mascara, gel, toothpaste;

Pharmaceuticals: ointment, dental composite, syrup, injection;

Food: mayonnaise, dressing, jam, butter, margarine, wasabi;

Chemicals: polyester, synthetic fiber, shoe cream;

Options

Fixed cover with bolts or welding to save budget;

Frame type slow agitator for oil pre-mixer;

Mettler-Toledo load cells;

Siemens PLC for automation of mixing, dispersing, emulsifying, homogenizing, vacuum, transferring, heating and cooling etc;

Flow meter automation for feeding liquid oil and water;

Pressure vessel design for different steam pressure;

SIP is available upon request;

Different power supply acceptable;

Project case:

Our mixer machine with wide range of food products designed as per demand our customer , Many our mixer for pickles, chutneys, ready to eat items, paste and sauces, frozen foods and spices , Garlic Chutney, Mint Chutney and Tamarind Chutney; Sweet Mango Chutney, Mango Ginger Chutney and Hot Mango Chutney , Mayonnaise Production Line/ machines and equipment.

Our Mixer and plant with vacuum emulsifying homogenizer mixer/ manufacturing plant and machine , Our production plant is use made with homogenizing mixer, Stainless Steel oil phase mixer, water phase mixer with vacuum system, hydraulic lifting line, Pump with materials circulation system, Product tank with heating and cooling system, temperature control system and electrical control panel etc.

Guangdong Jinzong Machinery Co., Ltd. is a professional manufacturer of chemical, biological & pharmaceutical machinery and equipment more than 20 years .

Please do contact us should you have any inquiries about our product.

condiment baby food Mayonnaise Production Line mixing machines and equipment manufacturer

The product has a wide range of applications in the industry due to its huge prospects. The product has an automatic data collection function.

This product meets the evolving application needs of customers. The product has an automatic data collection function.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. www.jinzongmachinery.com| Sitemap Privacy Policy