Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

China Stainless Steel Plate Frame Filter

| Model NO. | WBG | Trademark | Jinzong Machinery |

| Transport Package | Plywood Case | Specification | CE, ISO, SGS |

| Origin | Guangdong, China(Mainland) | HS Code | 8419500020 |

Production introduction

The equipment is multi-layer frame filter, which is applicable to the process operation with the requirement of fine filtration and semi-fine filtration such as purification ,sterilization and defecation with sealed filtration in the liquid with low viscosity and little slagging content under the concentration of 50%,by directly adopting microporous filtration film, it can realize the sterile filtration without passing the microporous film.

Features

1) The machine is made of 1Crl8Ni 9Ti or 316L high quality stainless steel, corrosion resistant and durable.

2) The filter plate due to use of a screw structure, according to the filtrate of the different production processes (early filter, semi-fine filter, fine filter) requires the replacement of different filter (direct selection of microporous membrane can not go through the microporous membrane Can achieve the purpose of sterile filtration). Users can also according to the size of the production flow, the corresponding reduction or increase filter plate.

3) All parts of sealed parts of the installation of the ring (milky white silicone rubber seals, non-toxic high temperature), no leakage, good sealing performance.

4) The machine work for the pressurized closed filter, liquid material without loss. Liquid clarity is good, in addition to bacteria (the use of medium-speed filter paper and microporous membrane sterilization effect is particularly good).

5)The machine can also be based on user needs, specially equipped with automatic return channel, after the pump stops rotating, open the return valve (both deflation function) all the automatic discharge of sediment discharge. In the filter high viscosity liquid, can make the liquid flow unimpeded, can make a variety of impurities automatically reflux discharge. At the same time with the water from the backhammer back to the filter for temporary cleaning and for the convenience.

6)The pump and the input tube part of the connection by the three fold-type ring, a solid seal, easy to unload cleaning

| Type | Layers | Filtration Area(m2) | Filter Material Size (mm) | Membrane Pore Size (um) | Filtration Pressure(Mpa) | Water Flow(T/h) | Motor (Kw) | Dimension(mm) |

| WBG-100 | 10 | 0.078 | Φ100 | 0.1~50 | 0.15 | 0.8 | 0.55 | 600×300×600 |

| WBG-150 | 10 | 0.170 | Φ150 | 0.1~50 | 0.15 | 1.5 | 0.75 | 650×380×650 |

| WBG -200 | 10 | 0.314 | Φ200 | 0.1~50 | 0.15 | 2.0 | 1.1 | 650×400×700 |

| WBG -300 | 10 | 0.700 | Φ300 | 0.1~50 | 0.15 | 4.0 | 1.1 | 700×500×800 |

| WBG -400 | 10 | 1.250 | Φ400 | 0.1~50 | 0.15 | 6.0 | 1.1 | 900×600×1000 |

| WBG -400 | 16 | 2.000 | Φ400 | 0.1~50 | 0.15 | 9.0 | 1.5 | 1000×600×1000 |

| WBG -400 | 20 | 2.500 | Φ400 | 0.1~50 | 0.2 | 10.0 | 1.5 | 1100×600×1000 |

| WBG -400 | 32 | 4.000 | Φ400 | 0.1~50 | 0.3 | 13.0 | 2.2 | 1320×600×1000 |

| WBG -500 | 12 | 2.000 | Φ500 | 0.1~50 | 0.3 | 8 | 1.5 | 1100×720×1200 |

| WBG -500 | 16 | 3.000 | Φ500 | 0.1~50 | 0.3 | 13 | 2.2 | 1350×720×1200 |

| WBG -500 | 22 | 4.000 | Φ500 | 0.1~50 | 0.3 | 16 | 2.2 | 1350×600×1200 |

| WBG -500 | 26 | 5.000 | Φ500 | 0.1~50 | 0.3 | 20 | 3.0 | 1350×720×1200 |

| Note:flow plate frame filter can be customized | ||||||||

Packaging:

Packed by wooden case usually.

According to customer's requirement, other packaging is available as well.

Shipping:

European Countries: 22-28 days

United States: East --13-16 days, West--21-28 days

Brazil: 30-40 days

Russia: 36 days

Asia Countries: 3-5days

Our Services:

Pre-sales service:

1> Engineering design

2> Equipment model selection guide

3> equipment machinig

After-sales service:

1> one year from date of delivery, if any spare parts be broken within warranty and not caused by improperly operation, we would offer the new parts for free.

2> Provide professional after-sales service engineers to abroad installation and debugging.

company information:

Jinzong Machinery is a manufacturer of processing machines ( crusher,reactor, mixing tank, high speed disperser, sand mill, filling machine , paint&coating production line) for chemcial industry with more than 20 years experiences and best service in China, which covers an area of 1,7000 square meters, has 5 workshops now.

1.Why do you choose us?

·High quality and competitive price.

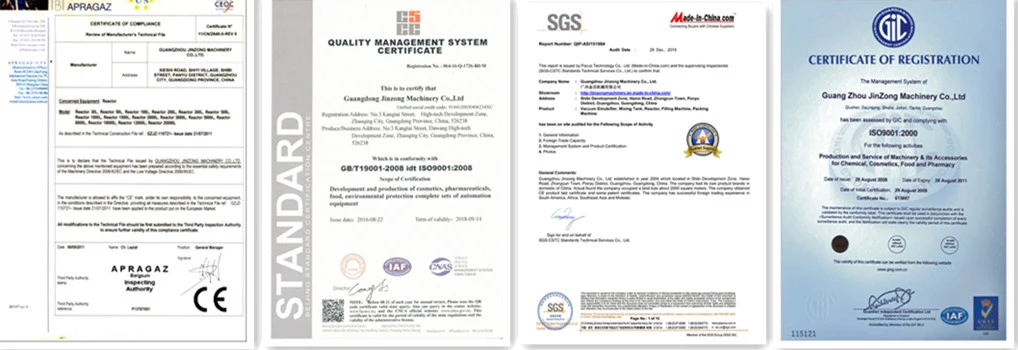

·Approved by ISO, CE, GS and etc.

·One year warranty; perfect after-sales service for spare parts.

·Easy maintenance.

2.What kind of machines can you supply to customer?

We could offer various kinds of machines and whole production line.

(1) Vacuum emulsifying machines series

Upper-homogenizer vacuum emulsifying mixer

High-efficiency vacuum homogenzing emulsifying mixer

Tilting vacuum homogenzing emulsifying mixer

Fixed type vacuum emulsifying mixer with internal&external circulation

Fixed type homogenzing emulsifying mixer

Compact type vacuum omogenzing emulsifying machine

Multifunctional laboratory emulsification machine

(2) Liquid detergent production line

(3) Liquid detergent mixer

(4) Sanitary storage tank

(5) Perfume freezing machine

(6) Power equipment

(7) Lipstick equipment

(8)Filling machine

Automatic cream& paste filling machine

Automatic liquid filling machine

Semi-automatic ointment and liquid filling machine

Automatic cosmetic facial masks filling and sealing machine

Automatic tube filling and sealing machine

Automatic lainated tube filling& sealing machine

(9)Labeling machine

Multi-function flat&round bottles labeling machine

(10) Auxiliary equipment series

Packing machine

Sealing machine

Conveyor table

Capping machine

Auxilary equipment

Steam generator

Laboratory equipment

company information:

Jinzong Machinery is a manufacturer of processing machines (vacuum emulsifying homogenizer mixer, liquid detergent production,storage tank, filling&packing machine,etc) for chemcial industry with more than 20 years experiences and best service in China, which covers an area of 1,7000 square meters, has 5 workshops now.

Our Certificates

Choose JINZONG, choose contentment

Please contact me if you are interested and have any questions

↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)