Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

best inline homogenizer company for stationery industry

| Model NO. | JRK | Customized | Customized |

| Condition | Used | Warranty | 1 Year |

| Capacity | 10-1000L | Material | Full Stainless Steel |

| Trademark | Jinzong Machine | Transport Package | Wooden Case |

| Specification | SGS | Origin | Guangdong |

JRK series Cosmetic Vacuum Homogenizing Emulsifying Machine/Jrk series Mascara making machinery

1. 50-1000L

2. Cosmetic cream, gel and lotion making machine

3.GMP, FDA

JRK series Cosmetic Vacuum Homogenizing Emulsifying Machine

Cosmetic Machine JRK series Vacuum Homogenizing Emulsifying machine is developed on the basis of JR fixed emulsifying machine and can be lifted the cover and pour the boiler to discharge, easy to wash.

Features:

1.High efficient emulsifier: it is a high efficient German compound homogeneous emulsifier with six-layer shear teeth of special structure, shearing more times, transient partial pressure up to 100Mpa above .its emulsification effect for materials which goes through the emulsifier is dozens of times than that of common ones.

2.Precision motion mechanism and cooling system: high efficiency, power loss is small, heterogeneous devices can work long time, the application of special process requirements

3.Dead space-free multi-functional flow disturbance stirring system: it may effectively improve the stirring rate and mixing effects;

4.Production of non-dead, out of less material residue: the JRKA homogeneous emulsifier type on the same machine, than the other types of emulsion is better;

5.The cover of the main boiler can lift : to ensure that maintenance and cleaning easy;

6.All lifting system uses hydraulic mechanism to ensure the smooth movement, accurate, and security;

7.Manual control, operation and easy maintenance.

Main boiler has the vacuum pressure of -0.08Mpa, the speed of rake stirrer is 7~60rpm with frequency control. The bottom homogenizer's revolution speed has 1400 and 2800 rpm two gears. It proves to be the perfect device for manufacturing medium&high-grade ointment and honey products.

Model Type:

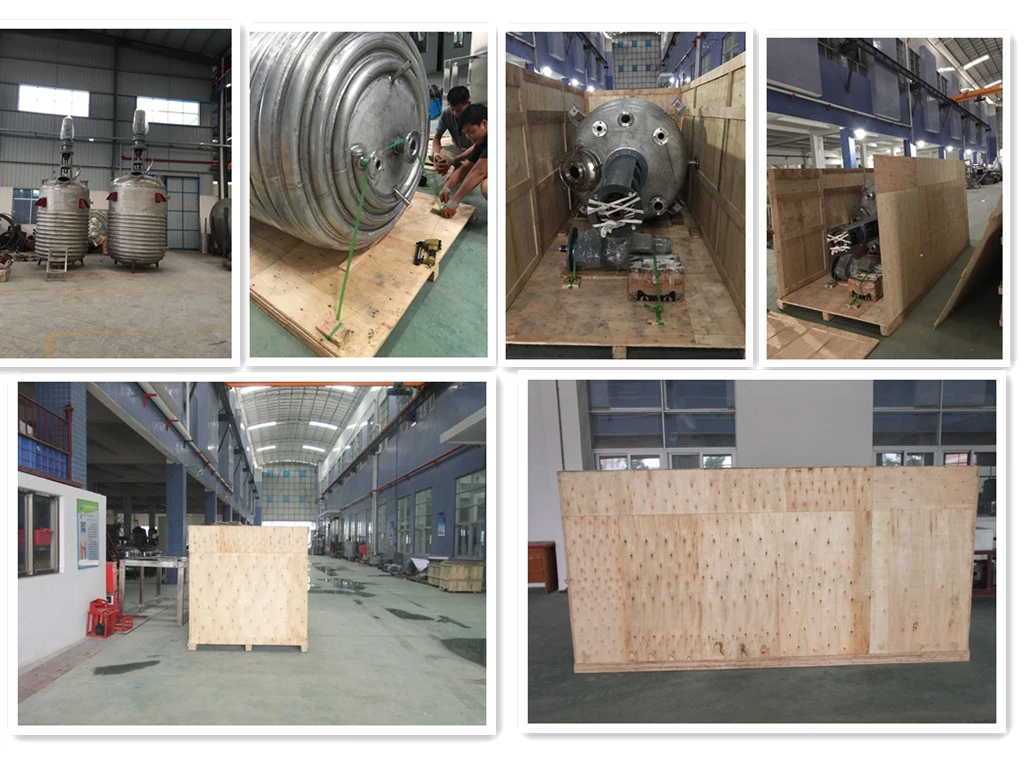

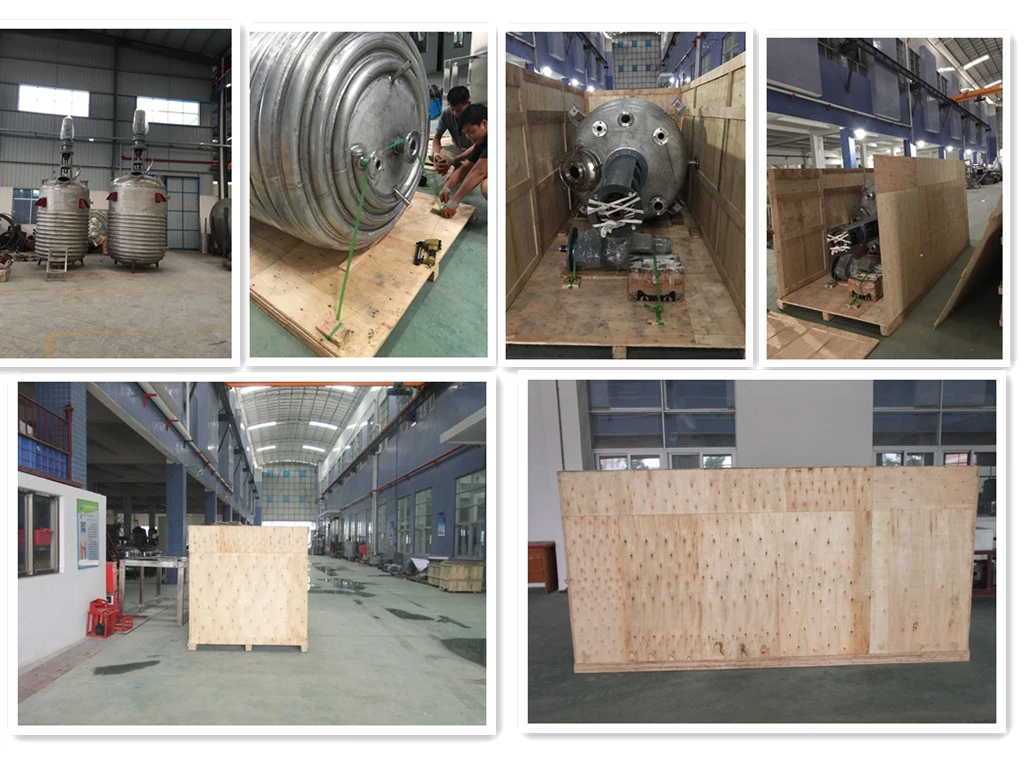

Packaging

1> Outer packing: plywood case

2> Inner packing: PE film wrapping overall

Packageing Show

Shipping:

Shipping:

FOB port: Guangzhou or Shenzhen

Our Services

We are not only professional manufacturer, but also the best solution provider!

Pre-sales service:

1> Engineering design

2> Equipment model selection guide

3> equipment machinig

After-sales service:

1> one year from date of delivery, if any spare parts be broken within warranty and not caused by improperly operation, we would offer the new parts for free.

2> Provide professional after-sales service engineers to abroad installation and debugging.

Company Information

We are a professional manufacturer of cosmetic,chemical& pharmaceutical machinery and equipment more than 17 years .Product lines range from:

1> Cosmetic Machinery: water treatment ,vacuum emulsifying machine,liquid detergent mixing machine,storage tank,solid soap making machine,perfume making machine, filling machine etc.

2> Chemical Machinery: reactor, mixing equipment,separation equipment, storage tank etc.

3> Pharmaceutical Machinery: vacuum ointment machine,sanitary stainless reaction pot,alcohol deposition can, collocation tank etc.

Factory and Workshop

Why us?

1. Experienced workforce: more than 17 years

2. Excellent quality range of industrial process equipment ,80% materials and components are purchased from 3M, ABB, Siemens, Panasonic, Schneider

3. Strict quality controls

4. Good reputation in industry.

5. Customized packaging

6. Simple ordering process

7. Easy payment modes

8. Prompt delivery

9. Have a Professional after-sales service engineering team

Our factory:

JINZONG ENTERPRISE is a technology innovation enterprise for integrating design, manufacturing and system integration of cosmetic machinery & equipment.With 20 years development,Jinzong has four wholly-owned subsidiary,and Guangzhou Jinzong Machinery Co.,Ltd & Guangdong Jinzong Machinery Co.,Ltd,which is under the jurisdiction of Cosmetic Division & International Trading Division,is responsible for complete sets equipment's design,manufacturing,project solution of cosmetic cream manufacturing machines,liquid detergent making machines,make-up products making machines.

JINZONG ENTERPRISE has over 20,000 square meters production base;Guangzhou Jinzong its covers an area of 8,000 square meters,Guangdong Jinzong its cover and area of 17,000 square meters,and Jinzong has been service over 2,000 customers around the world.

JINZONG ENTERPRISE has been cooperating with university & scientific research academy for researching & technical improving the production technology since 2004.Jinzong has professional & experienced technical team to design & manufacture the products in accordance with ISO quality management system,Jinzong has professional project installation team and after-sales service team for providing best service to our clients.

JINZONG ENTERPRISE production is based on the "efficiency, safety, and environment friendly"; "quality first, service-oriented" as a fundament,; constantly beyond, Jinzong will always provide better products and services to clients!

1. 50-1000L

2. Cosmetic cream, gel and lotion making machine

3.GMP, FDA

JRK series Cosmetic Vacuum Homogenizing Emulsifying Machine

Cosmetic Machine JRK series Vacuum Homogenizing Emulsifying machine is developed on the basis of JR fixed emulsifying machine and can be lifted the cover and pour the boiler to discharge, easy to wash.

Features:

1.High efficient emulsifier: it is a high efficient German compound homogeneous emulsifier with six-layer shear teeth of special structure, shearing more times, transient partial pressure up to 100Mpa above .its emulsification effect for materials which goes through the emulsifier is dozens of times than that of common ones.

2.Precision motion mechanism and cooling system: high efficiency, power loss is small, heterogeneous devices can work long time, the application of special process requirements

3.Dead space-free multi-functional flow disturbance stirring system: it may effectively improve the stirring rate and mixing effects;

4.Production of non-dead, out of less material residue: the JRKA homogeneous emulsifier type on the same machine, than the other types of emulsion is better;

5.The cover of the main boiler can lift : to ensure that maintenance and cleaning easy;

6.All lifting system uses hydraulic mechanism to ensure the smooth movement, accurate, and security;

7.Manual control, operation and easy maintenance.

Main boiler has the vacuum pressure of -0.08Mpa, the speed of rake stirrer is 7~60rpm with frequency control. The bottom homogenizer's revolution speed has 1400 and 2800 rpm two gears. It proves to be the perfect device for manufacturing medium&high-grade ointment and honey products.

Model Type:

Model# | Volume of Main Boiler (L) | Volume of Pretreament Boilers (L) | Dimensions (LxWxH) | Total Power (KW) | Net Weight (KG) |

| 50 | 75 | 45/65 | 2700x2300x1950-2650 | 9 | 1600 |

| 100 | 130 | 70/100 | 2900x2700x2050-2800 | 10 | 1800 |

| 200 | 260 | 120/190 | 3200x2900x2350-3300 | 13 | 2200 |

| 300 | 375 | 150/260 | 3350x3000x2550-3650 | 17 | 2500 |

| 500 | 620 | 300/460 | 3800x3400x2800-4050 | 25 | 3300 |

| 1000 | 1250 | 620/900 | 4150x4150x3700-5200 | 32 | 5000 |

1> Outer packing: plywood case

2> Inner packing: PE film wrapping overall

Packageing Show

Shipping:

Shipping:FOB port: Guangzhou or Shenzhen

Our Services

We are not only professional manufacturer, but also the best solution provider!

Pre-sales service:

1> Engineering design

2> Equipment model selection guide

3> equipment machinig

After-sales service:

1> one year from date of delivery, if any spare parts be broken within warranty and not caused by improperly operation, we would offer the new parts for free.

2> Provide professional after-sales service engineers to abroad installation and debugging.

Company Information

We are a professional manufacturer of cosmetic,chemical& pharmaceutical machinery and equipment more than 17 years .Product lines range from:

1> Cosmetic Machinery: water treatment ,vacuum emulsifying machine,liquid detergent mixing machine,storage tank,solid soap making machine,perfume making machine, filling machine etc.

2> Chemical Machinery: reactor, mixing equipment,separation equipment, storage tank etc.

3> Pharmaceutical Machinery: vacuum ointment machine,sanitary stainless reaction pot,alcohol deposition can, collocation tank etc.

Factory and Workshop

Why us?

1. Experienced workforce: more than 17 years

2. Excellent quality range of industrial process equipment ,80% materials and components are purchased from 3M, ABB, Siemens, Panasonic, Schneider

3. Strict quality controls

4. Good reputation in industry.

5. Customized packaging

6. Simple ordering process

7. Easy payment modes

8. Prompt delivery

9. Have a Professional after-sales service engineering team

Our factory:

JINZONG ENTERPRISE is a technology innovation enterprise for integrating design, manufacturing and system integration of cosmetic machinery & equipment.With 20 years development,Jinzong has four wholly-owned subsidiary,and Guangzhou Jinzong Machinery Co.,Ltd & Guangdong Jinzong Machinery Co.,Ltd,which is under the jurisdiction of Cosmetic Division & International Trading Division,is responsible for complete sets equipment's design,manufacturing,project solution of cosmetic cream manufacturing machines,liquid detergent making machines,make-up products making machines.

JINZONG ENTERPRISE has over 20,000 square meters production base;Guangzhou Jinzong its covers an area of 8,000 square meters,Guangdong Jinzong its cover and area of 17,000 square meters,and Jinzong has been service over 2,000 customers around the world.

JINZONG ENTERPRISE has been cooperating with university & scientific research academy for researching & technical improving the production technology since 2004.Jinzong has professional & experienced technical team to design & manufacture the products in accordance with ISO quality management system,Jinzong has professional project installation team and after-sales service team for providing best service to our clients.

JINZONG ENTERPRISE production is based on the "efficiency, safety, and environment friendly"; "quality first, service-oriented" as a fundament,; constantly beyond, Jinzong will always provide better products and services to clients!

mechanical equipment is packed in a sound and safe way. The product is highly automatic and controllable.

Guangdong Jinzong Machinery Co., Ltd. implements comprehensive quality inspection measures in all aspects of production. The product is highly automatic and controllable.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. www.jinzongmachinery.com| Sitemap Privacy Policy