Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

accurate Intermediate manufacturing plant yga company for reflux

Proteins hydrolysis plant preparation of amino acids

*Process include:

Hydrolysis

Centrifugal separation

Neutralization and filtration,Decolorization

Distillation

Drying

Packing

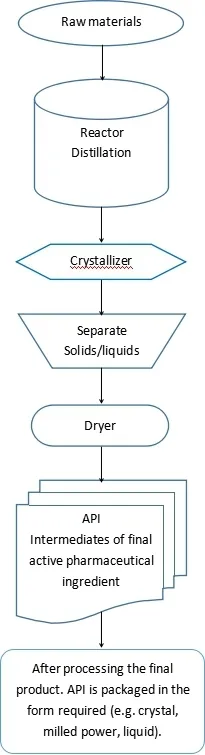

*MAIN COMPOSITION of API manufacturing plant:

API manufacturing plant consist the following equipments and accessories: reactors, mother liquor, storage tank, condenser, crystallizer, slurry tanks, filter, centrifuge machine, dryer, transfer pumps.

*Features:

◪ Design compliance with cGMP.

◪ Customized;

◪ Available model from pilot plant to large scale manufacturing plant;

*API manufacturing plant:

Jinzong provides a full range of integrated solutions from R & D Lab test, pilot prodution to large scale production for the API industry, and provides pharmaceutical manufacturer with complete upstream and downstream of API process system design, which can meet the process requirements of different production lines of clients, including fermentation, extraction, chemical synthesis and related supporting systems, and assist customers to achieve high standard and high efficiency process flow.

Jinzong provides an intelligent API engineering integration solution for a pharmaceutical industry, covering the turnkey project design, process optimization and automation control implementation. The project reflects the characteristics of Jinzong API technology "originated from process design and service process production", helps customers realize process optimization, improve production efficiency, and strive to build API process pipeline and automatic control demonstration project.

Questions? We can help! Contact us to discuss your project.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)