Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery high quality cream filling machine high speed for petrochemical industry

1. The raw material of Jinzong Machinery labeling machine is strictly controlled from beginning to finish.

2. cream filling machine can serve labeling machine due to such advantages such as vacuum emulsifying mixer .

3. cream filling machine has applications in a wide range of fields, including labeling machine .

4. Guangdong Jinzong Machinery Co., Ltd. has strong capacity and its sales network is throughout the country.

*Description:

Automatic liquid and cream filling machine is the latest development of our company. The machine can be used for the industry of pharmacy, food, grain and edible oil, grease, oil chemicals, daily chemicals, cosmetics and new materials industries etc.

It can improve production efficiency, reduce the operation intensity, improve the working environment and ensure the filling precision, it is the ideal filling quantitative packaging equipment.

*Principle:

Automatic paste liquid filling machine can realize automatically fill. The filling volume, filling velocity, filling precision,filling height, and filling position can be adjusted by the machine.

It is mainly composed of storage tank,the main control cabinet,operation panel,filling the lifting frame parts,pneumatic filling nozzle part,the detection switch& sensor,selector lever,conveying hose, a signal line, power line and other components and accessories. The equipment adopts the modular combination of installation, the main parameters and the set was completed in the operation panel.

The filling process includes: 0 Setting & debugging; ① Take bottles of bottles storage; ②Empty bottles into the conveyor belt;③ Conveying the bottles; ④The back guardrail stopped bottles; ⑤Quantitative filling; ⑥In front guardrail stopped bottles; ⑦The completion of filling,The back guardrail output bottles; ⑧The back guardrail stopped bottles; ⑨In front guardrail output bottles.

When the device is working, require a labor constantly place bottles in front of the equipment, make sure to keep filling.

Note: the equipment in the installation and commissioning, operation, maintenance shall be understood clearly, to avoid the accident loss and accident.

| Filling Volume (ml) | Productivity (b/h) | Filling speed (adjustable) | Filling Precision | Air Supply |

| 10-50 | 1500-3500 | adjustable | ≤±1% | 0.4-0.8MPa |

| 80-300 | 1500-3000 | adjustable | ≤±1% | 0.4-0.8MPa |

| 100-500 | 1500-2500 | adjustable | ≤±1% | 0.4-0.8MPa |

| 300-1000 | 1500-2500 | adjustable | ≤±1% | 0.4-0.8MPa |

| 1000-5000 | 1000-2000 | adjustable | ≤±1% | 0.4-0.8MPa |

◪ Control component and actuator is using the good brand element.All parts contact with product are made of SUS304/SUS316L. Non-metallic parts adopt high standard materials.

◪ Conveyor shell is made of SUS304, durable. Conveyor running smoothly, stepless speed regulation, uniform strong load capacity.

◪ PLC control. The feeding pipe is made of PVC steel pipe.Because the one-way valve is a quickly and accurately cylinder valve, so filling high precision of the equipment, small error.

◪ The machine has automatic transfer bottle, automatic lifting filling nozzle, quantitative filling, uniform filling, emergency stop.

◪ This machine use the cylinder valve filling nozzle.Leakproof plug is arranged in the filling nozzle, prevent the filling nozzle wiredrawing, dropping material.

◪ The machine parts (host, hose, filling nozzle) connected by a fast joint. No special tools required to install.Convenient disassembly, cleaning, maintenance, assembly.

Company Features

1. Jinzong Machinery is very extraordinary in the cream filling machine industry.

2. mixing tank design is backed up by advanced production equipment, professional scientific and technical personnel.

3. Guangdong Jinzong Machinery Co., Ltd. will seize the opportunity to continue the rapid and healthy development of itself in cosmetic filling machine industry. Ask online! Based on the tenet of labeling machine concept, the company has achieved great development. Ask online! It is the eternal tenet for Guangdong Jinzong Machinery Co., Ltd. to pursue vacuum emulsifying mixer . Ask online!

PRODUCT DESCRIPTION

Major Characteristics:

1. Rotary piston filling, high efficiency with high production capacity.

2. PLC controlled. Easily connected with capping machine and labeling machine and implementing Bus Communication.

3. Two channel standard safety electric circuit to make sure equipments running safely.

4. With AUTO-ID system. No bottle no filling.

5. Servo drive piston, high-precision filling

6. Adopting diving filling to avoid foamy and explosion.

7. Eternal wear free measuring cylinder, long working life Pan plug seal with the function of self-compaction, maintenance free.

Technical parameter:

NO. | Items | Performance |

01 | Power Supply | AC 220V ;50Hz or 380V; 50Hz |

02 | Power | 2.2kw |

03 | Suitable containers | Container mouth diameter: ≥Φ18mm (can be customized) |

Container height:100mm-300mm (can be customized) | ||

Container diameter:30mm-100mm (can be customized) | ||

04 | Number of filling nozzles | 24(may customized) |

05 | Productivity | ≤100b/min (for 1.5L) |

06 | Pneumatic (air -operated) source | 0.33-0.50 Mpa clean and Stable compressed air |

07 | Material density: | 0.6-1.3 |

08 | Machine weight | 650Kg |

09 | Dimension(L*W*H) | 2000mm*1200mm*2500mm |

PRODUCT PICTURES

COMPANY INFORMATION

PACKAGING & SHIPPING

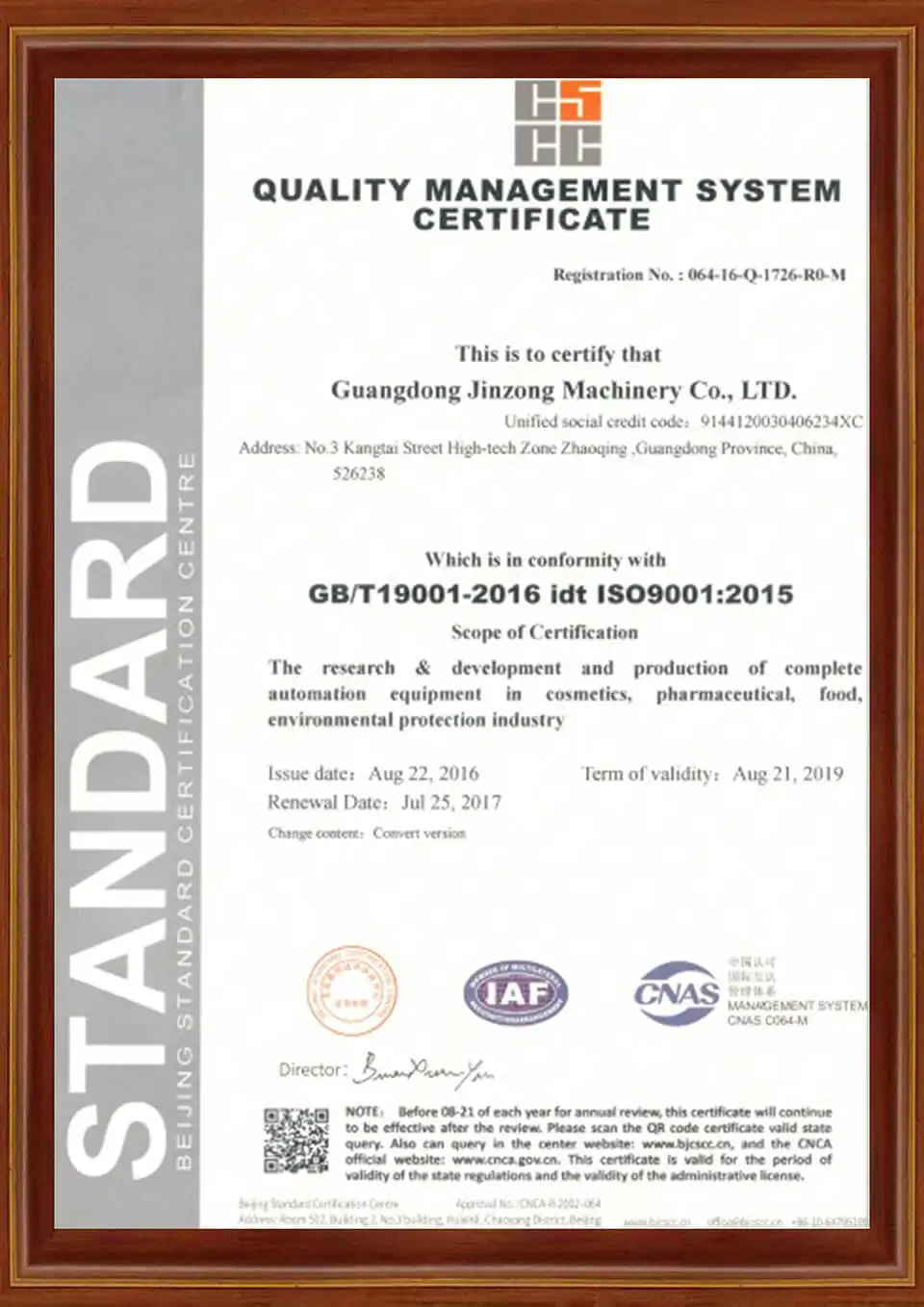

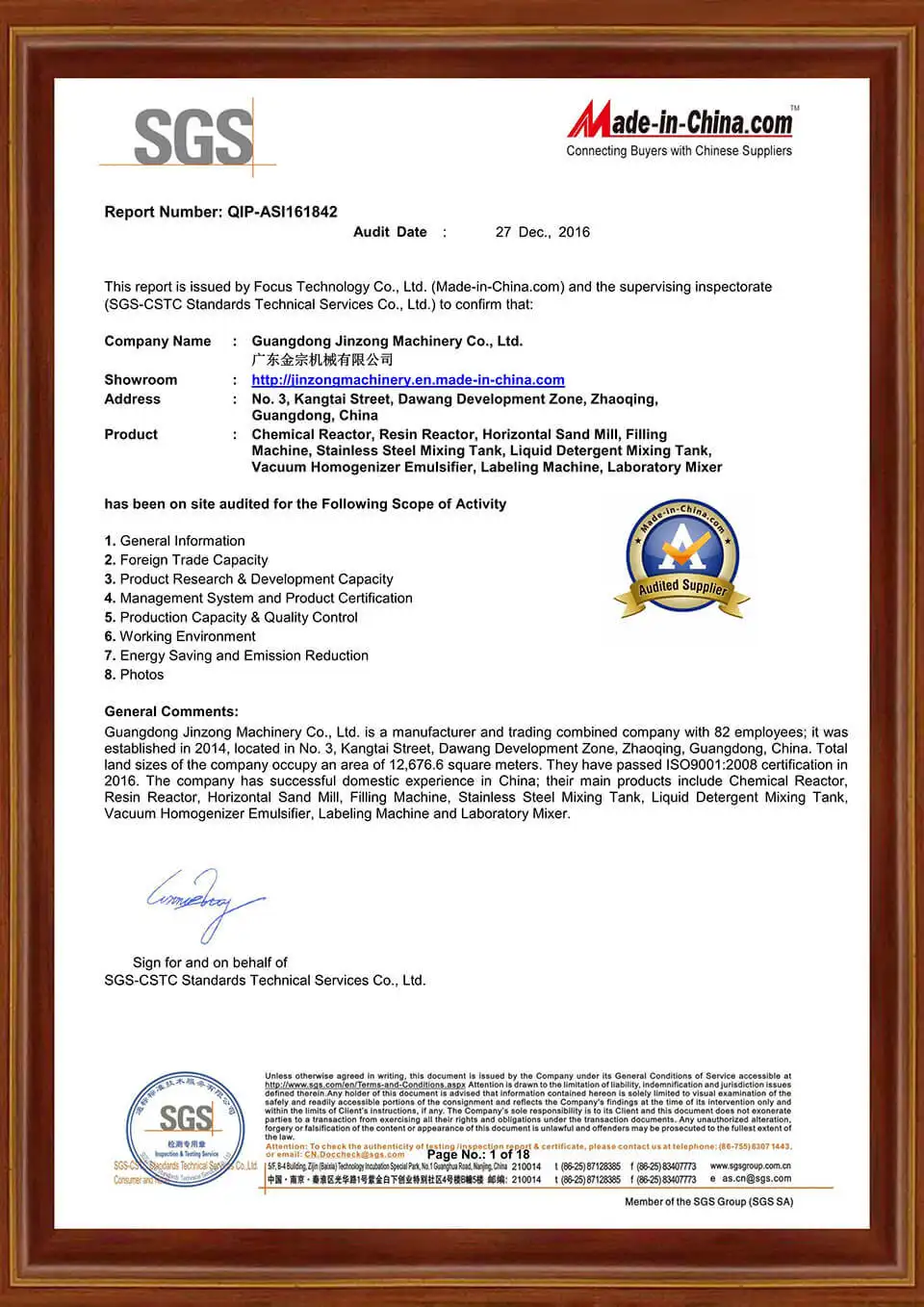

CERTIFICATE

PAYMENT METHOD

OUR SERVICES

China packaging machinery industry gathering

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)