Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery emulsifying labeling machine online for petrochemical industry

1. Jinzong Machinery is manufactured by our well-trained workers using advanced technology.

2. Chemicals emitted from this product will not be a potential source of health problems as these chemicals have been properly addressed.

3. The product is very resistant to rust. Because it is sufficiently reactive to protect itself from further attack by forming a passive corrosion product layer.

4. This product is increasingly used in the market due to its significant economic benefits.

5. This product has significant economic benefits and good application prospects.

*Description:

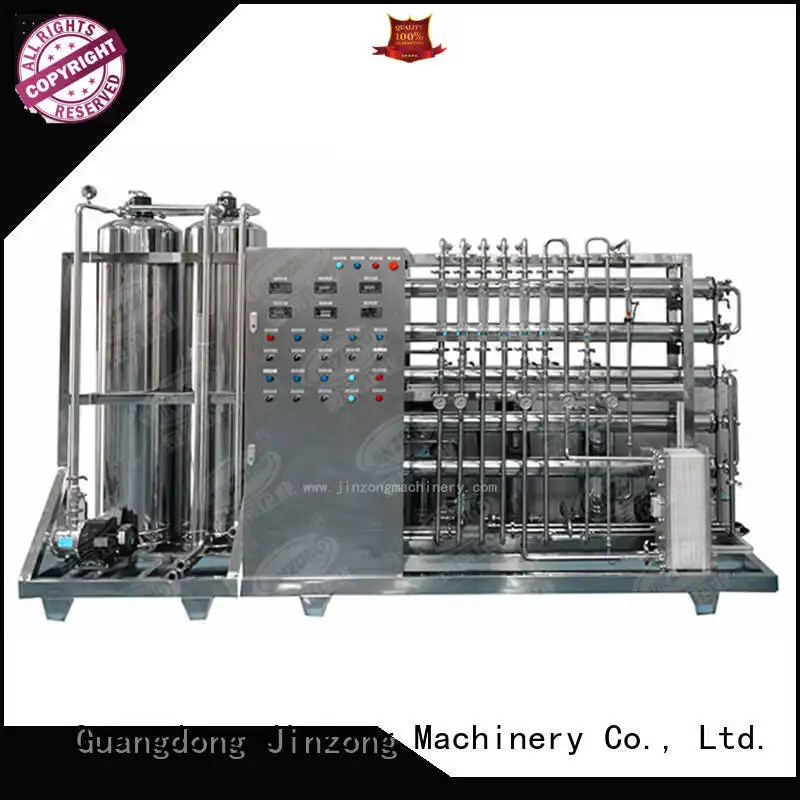

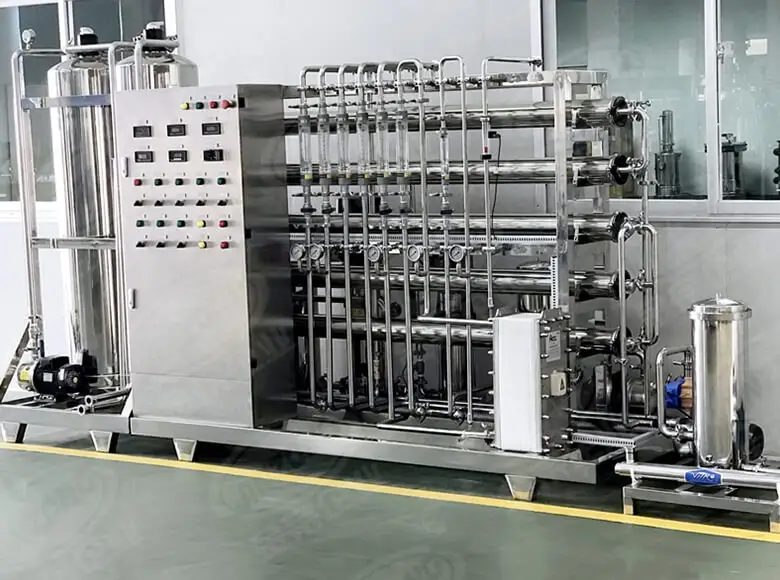

The water treatment machine is suitable for such industries as cosmetics, pharmacy, food and electronics has been deeply favored by users for its stable water quality and simple operation.

The system solves the troubles of frequent regeneration and cleaning during the use of ion exchanging water purifier. By adopting physical principle, it enables the water to pass the reverse osmosis film with a diameter of one ten-thousandth of a micron and separates impurities, ion, microbes and colloids in the water, so as to meet the water requirements in cosmetics industries.

Reverse osmosis process uses semi permeable spiral wound membranes to separate and remove dissolved solids, organic, pyrogens, sub micron colloidal matter and bacteria from water. Feed water is delivered under a pressure of approximately 16 kg/cm2 through reverse osmosis membranes. Water permeates the minute pores of the membrane and is delivered as purified water. Impurities in the water are concentrated in the reject stream and flushed to drain. Reverse osmosis is capable of removing 90%-99% of total dissolved solids (TDS), 99% of organic, including pyrogens, and 99% of all bacteria in the feed water.

According to the customer's local water testing report,we adopt different equipments to produce drinking water of pure water or mineral water,etc.

*Features:

1. Continuous production, no need to regenerate, reduce labor intensity;

2. High efficiency, fully automatic operation, easy to operate and maintain;

3. Online conductivity monitoring to ensure that the water output meets the requirements;>

4. Can remove organic matter and bacteria more than 98 %;

5. If the original water quality is poor or the water demand is high, JRO reverse osmosis can also be connected with ion exchange equipment to ensure various water requirements.

6. Can add anion & cation mixing bed,EDI,UV lamp,etc..

| Model | Productivity(t/h) | Power(kw) | Recovery rate(%) | Desalination rate(%) |

| JRO-0.5 | 0.5 | 1.5 | 50 | 97 |

| JRO-1.0 | 1.0 | 1.5 | 50 | 97 |

| JRO-2.0 | 2.0 | 1.5 | 70 | 97 |

| JRO-3.0 | 3.0 | 2.5 | 75 | 97 |

| JRO-5.0 | 5.0 | 5.5 | 75 | 97 |

| JRO-6.0 | 6.0 | 5.5 | 75 | 97 |

| JRO-8.0 | 8.0 | 7.5 | 75 | 97 |

| JRO-10.0 | 10.0 | 7.5 | 75 | 97 |

Chemical industry, power plant desalination water, electrodeionization ultra pure water, medical industry, aviation cleaning, food and beverage industry, municipal heating,

softened circulating water, living water purification, brackish water desalination, sea water desalination,industrial waste water treatment, reclaimed water reuse, rural area drinking water project, pharmacy inductries,etc.

Company Features

1. Guangdong Jinzong Machinery Co., Ltd. is one of the leading manufacturers for producing labeling machine .

2. Our company is located near to the consumer market. This not only helps reduce transportation and distribution costs but helps render quick services to the customers.

3. As the high expectations of Jinzong Machinery, we try our best to serve Liquid Detergent Mixer . Inquire now! Because of , Guangdong Jinzong Machinery Co., Ltd. can continuously improve product quality and service quality in the process of accumulating experience. Inquire now! For customers, Guangdong Jinzong Machinery Co., Ltd. always adheres to . Inquire now! Guangdong Jinzong Machinery Co., Ltd. will unswervingly adhere to high-quality development for cosmetic filling equipment . Inquire now!

Round Bottle Labelling Machine

Portable Tabletop Bottle Labelling Machine

1. Specifications of Portable Tabletop Vinegar Bottle Labelling Machine for Sale

Specifications of Semi-Automatic Round Bottle Labeling Machine | |

Labeling Speed | 1200-2400pcs/hour |

Labeling Accuracy | ±1mm |

Round Bottle Size | Outer dia:40-120mm, Height: 10-120mm |

Max Labeling Width | 10-120mm |

Max Labeling Length | 20-500mm |

Inner Core Size | Inner diameter: 70mm/ Outer diameter: 300mm |

Power | 220V, 50HZ, 100W |

Machine Size | 600*600*650mm |

Machine Weight | 30Kg |

2.Features of Portable Tabletop Vinegar Bottle Labelling Machine for Sale

1). --Adopt imported electromagnetic clutch with best accuracy.

2). --The machine shell adopts high class aluminum alloy anodic treatment, with long life span service.

3). --Adopt famous factory electric motor to ensure high load and long period operation.

4). --All parts and standard components are carefully made of stainless steel.

5). --With PLC control panel, liquid crystal display, the operation is simple and convenient, the function is stable.

6). --Imported label inspection optical coupler can ensure high precision.

7). --There is a code printer on the machine, so the machine also can print three lines like the expire date, valid date, batch number etc.

3.Applications of Portable Tabletop Vinegar Bottle Labelling Machine for Sale

1) labeling round bottles such as boxes, bottles, jars, cans, etc

2) Widely used in cosmetic, drinks, chemical, medical, food industry etc, which is can highly improve productivity and product quality.

4. Contact Informations:

| |

| Milk filling machine | water filling machine |

| Sleeve shrink labeling machine | Rotary capping machine |

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)