How much will it cost for cosmetic filling machine manufacturers production?

The total cost for cosmetic filling machine manufacturers production is the summation of direct materials, direct labor, and manufacturing overhead consumed during a given period. The direct materials will be directly processed into the finished products. Typically, the cost of the materials reflects the quality of the finished products in some way. As for direct labor, it includes not only the basic salaries and wages of all the workers employed in the manufacturing department but also any incentives and benefits they receive. Manufacturing overhead, by far is the final but also the most time-consuming determining the total cost of manufacturing. In conclusion, the total cost is priced considering each and every step of the above expenses incurred.

Guangdong Jinzong Machinery Co., Ltd. is equipped with modern production lines to manufacture cosmetic filling machine manufacturers . As one of Jinzong Machinery's multiple product series, cosmetic filling machine manufacturers series enjoy a relatively high recognition in the market. The product features the desired ductility. It has passed a low-temperature heat treatment process to reach the desired toughness ratio. It is highly resistant to UV light and flame. It is supposed to cater to all kinds of customers across the market. The product can realize mobile feeding and output.

Jinzong Machinery is ready to embrace different cultures. Contact!

Acrylic resin reactors are an essential component of many production processes, used in a wide range of industries including pharmaceuticals, chemicals, polymers, and more.

Acrylic emulsion reactors are widely utilized in the manufacturing of various coating formulations due to their numerous benefits.

Are you interested in learning about the principles and practices of emulsion polymerization reactors? Emulsion polymerization is a widely used industrial process for producing polymers in the form of latex.

Emulsion polymerization is an essential process in the production of a wide range of polymeric materials, including latex paints, adhesives, and synthetic rubbers.

Polyvinyl alcohol (PVA) reactors play a crucial role in the production of various industrial products such as adhesives, textiles, and films.

In the age of environmental awareness, the demand for biodegradable products is steadily increasing.

Epoxy Resin Reactors: A Comprehensive Overview

Epoxy resin reactors play a crucial role in the production of high-performance materials.

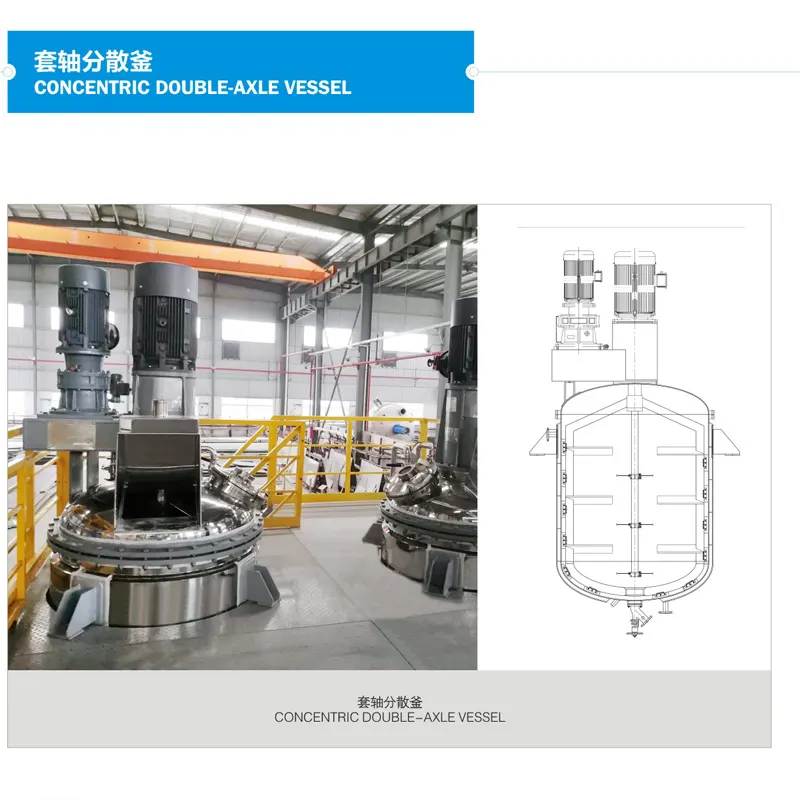

Jinzong Machinery was established in 1990s, it specializes in manufacturing of reactors, vacuum mixers, vacuum homogenizer mixers, disperser, mills, tanks and vessels, filling machine and resin plant etc. and the production system lines as well as undertaking the project construction EPC General Contractor for related industries.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)