Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

realiable powder mixer rollers high speed for workshop

-

v s

1. The manufacturing process of Jinzong Machinery sand mill manufacturers is quality oriented.

2. The product has to go through rigorous testing procedures which are conducted by our testing personnel before delivery. They are responsive to make sure that quality is consistently at its best.

3. The product meets the most stringent quality requirements and can be used for quite a long time.

4. To provide quality services to domestic and foreign merchants is Guangdong Jinzong Machinery Co., Ltd.'s constant pursuit.

*Description:

The basket is mainly composed of hydraulic lifiting system,transmission system,grinding system and so on. The hydraulic lifting system adopts the traditional hydraulic oil and the cylinder. The cylinder adopts the engineering cylinder. The cylinder is smooth and the hydraulic oil is less, And less oil spill phenomenon , hydraulic pump and motor place in the fuselage, no space, more compact, conducive to the maintenance and cleaning machine; transmission system using conventional pulley and conventional V-belt, the use of small noise process, more the use of imported bearings, long life, high speed noise small heat less; grinding system consists of all stainless steel material ,the basket stainless steel by heat treatment, high wear and corrosion resistance, the media using zirconia beads ,The bottom of the basket by the special leaves, play a pre-dispersed at the same time can make the bottom of the material up the roll, in order to achieve better grinding effect.

*Features:

1. Configure with qualified Inverter, various speed control

2. Hydraulic lifting, can be moved around

3. Integrate dispersing and grinding in one process

| Model | Capacity (L) | Power (Kw) | Speed (RPM) | Milling basket (L) | Lift stroke (mm) | Medium size (mm) |

| LS-11 | 100-400 | 11 | 0-1000 | 11 | 900 | 1.8-2.5 |

| LS-22 | 200-800 | 22 | 0-750 | 22 | 1100 | 1.8-2.5 |

| LS-30 | 300-1000 | 30 | 0-630 | 30 | 1100 | 1.8-2.5 |

| LS-37 | 300-1200 | 37 | 0-630 | 40 | 1100 | 1.8-2.5 |

◪ More than 20 years extensive experience in the machinery manufacturing in Cosmetic and cheimical biological & pharmaceutical industry.

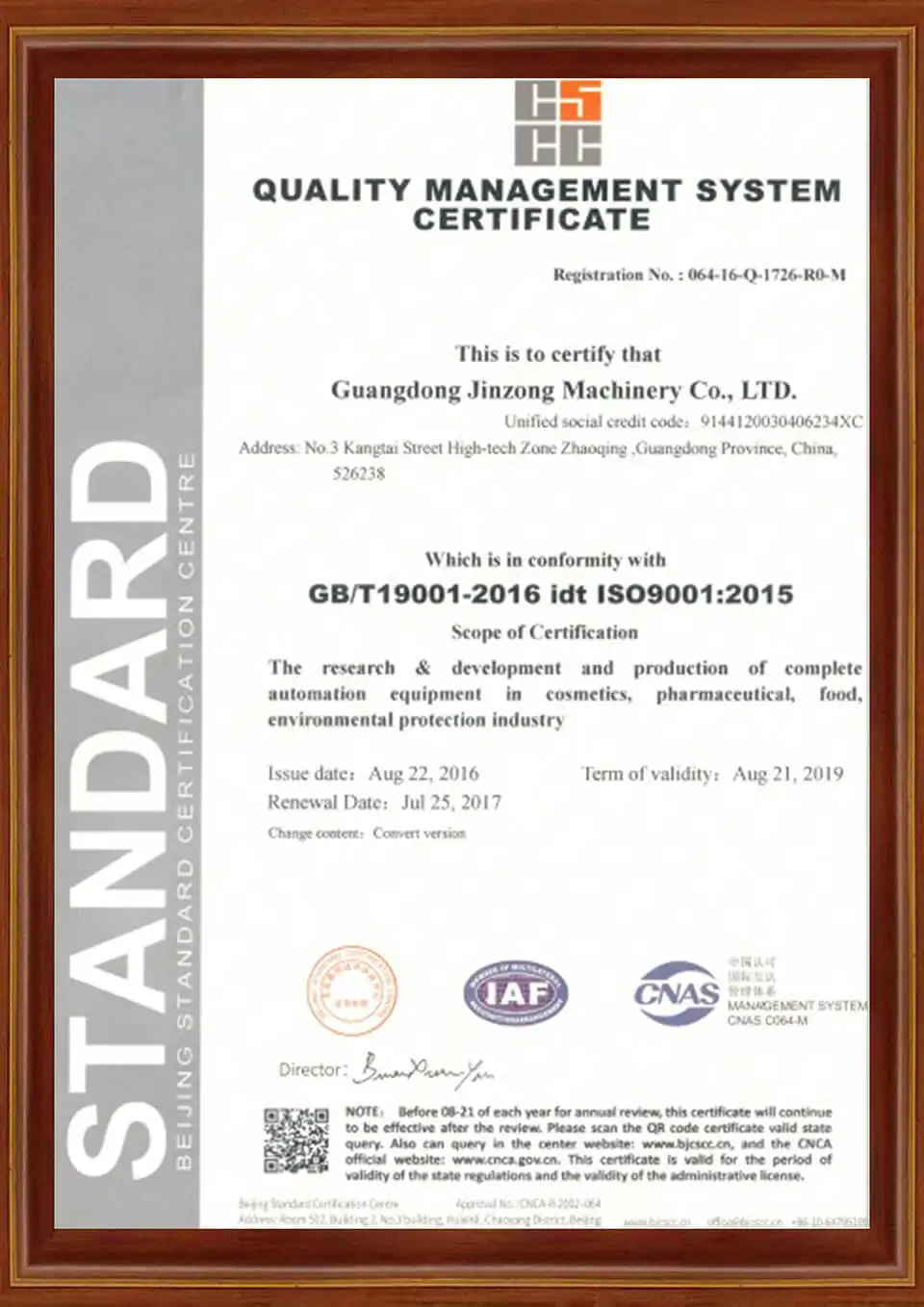

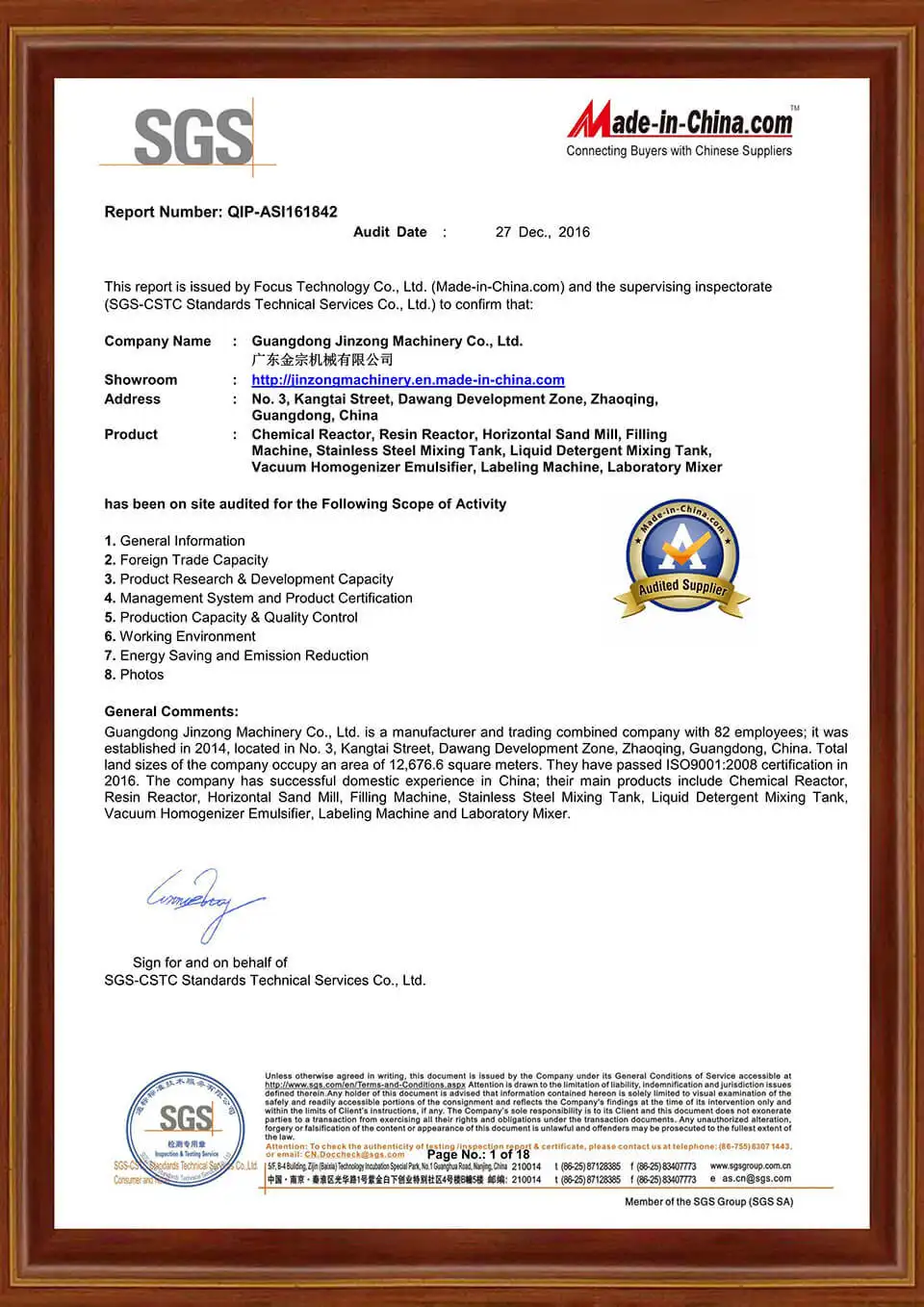

◪ Quality, 80% materials and components are purchased from 3M, ABB, Siemens, Panasonic, Schneider. Up to now, all core machinery are with CE Certificate. We carry out products designing, manufacturing, assembling and detection fully in accordance with ISO9001-2008 Quality Management System issued by Swiss SGS Company.

◪ Good reputation in industry. Many years are awarded "defend the contract heavy credit enterprise".

◪ Have a Professional after-sales service engineering team.

◪ Large scale plant. Currently, we have 2 processing bases, Zhaoqing factory, covering a total area of more than 17,000 square meters,and Shaoguan factory,covering a total area of more than 30,000 square meters. There are more than 160 sets of processing machinery including large vertical lathe, 5-axis horizontal machining center, large planer type milling machine, automatic polishing machines etc. With the help of our strong processing capacity, we produce more than 1000 sets of equipment every year.

Company Features

1. Guangdong Jinzong Machinery Co., Ltd. is a high-technical powder mixer enterprise.

2. Firmly grasping the advanced technology, Jinzong Machinery is able to offer the high-quality milling machine with competitive price.

3. Under the guidance of corporate management, Jinzong Machinery is growing toward a brighter future. Contact us! Guangdong Jinzong Machinery Co., Ltd. is a company who sticks to customer first always. Contact us! Maximized mutual benefits is Guangdong Jinzong Machinery Co., Ltd.'s biggest principle. Contact us! Jinzong Machinery's mission is to offer the best industrial powder mixer for customers. Contact us!

The machine is suitable for mixing dry powder material, different raw powder material and granular materials in pharmacy, chemical industry, food, fodder, pottery, metallurgy, etc.

This machine is no mechanical compression and strong friction, so it can maintain the intact of granular materials. It is made of stainless steel, which do not pollute the materials. In addition, this machine is equipped with timing device that can control the mixing time.

There will no further notification if the appearance or parameters of our products are modified. Thanks.

One-year warranty period for whole machine except of tubes and human factors etc, and 12-month of after-sale service from the date when you receive machine or 12 months when installation finished;

Consultant services for whole machine life, and 24 hours technical support by email;

UPS, English software, user manual and the installation & debugging by our experienced technicians.

1. Can your machine meet our need well?

We will supply you a proposal as to your specific requirement, and each machine is customized to satisfy customer's need well.

2. Are you a factory or a trading company?

We are the manufacturer, and have been in industry for more than ten years.

3. What's your payment way?

T/T by our bank account directly, or by Alibaba's trade assurance service, or by the West Union, or in cash.

4. How can you ensure the machine's quality after we put the order?

Before the delivery, we will send you machine's pictures and videos, or you can come to us to have the quality checking by yourself, or by the third party inspection organization contacted by your side.

5. We are afraid you won't deliver us the machine after we pay you the money.

Please note our above business license and certificates. And if you don't trust us, you can use Alibaba's trade assurance service or by LC.

6. Why choose your company?

We have been engaged in the manufacturing of various packing machines professionally over 10 years, and we can provide better after-sales service.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)