Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

realiable powder mixer horizontal high speed for factory

1. Jinzong Machinery sand mill machine was born out of innovation and curiosity.

2. Being a quality-oriented organization, we assure our clients that the product is highly durable.

3. It is recognized for strong durability and relatively long service life.

4. Wearing shoes made of this material means maximum comfort for feet. People won’t feel like walking miles in heavy shoes that cause pain and discomfort.

5. It will remain in place when worn. The interaction of gravity and fabric friction characteristics will not shift this garment over the body as the wearer moves.

*Description:

Jinozng Horizontal Nanomills system combines the well-known special separation system designed by Jinzong. This agitator bead mill was specifically developed by Jinzong engineers for high energy, high flow, multiple pass and specifically circulation operation grinding to achieve very narrow submicron particle size distributions with excellent repeatability.

Mainly designed for the middle and small lot manufacture of middle and high class product.

Using solvent discharging valve gear in the small mill barrel can make no material draffy remain in the barrel consequently reduce the waste.

This machine is very economic for middle and small manufacture and can meet more requirement of customer.

The high precision separation device can use those mill beads which has small diameter and get high output.

| Type | IN-6 | IN-10 | IN-30 | IN-60 |

| Tank capacity(L) | 6 | 10 | 30 | 60 |

| Motor power(KW) | 15 | 22 | 45 | 75 |

| Production capacity(KG/h) | 40-200 | 100-500 | 500-2500 | 1000-6000 |

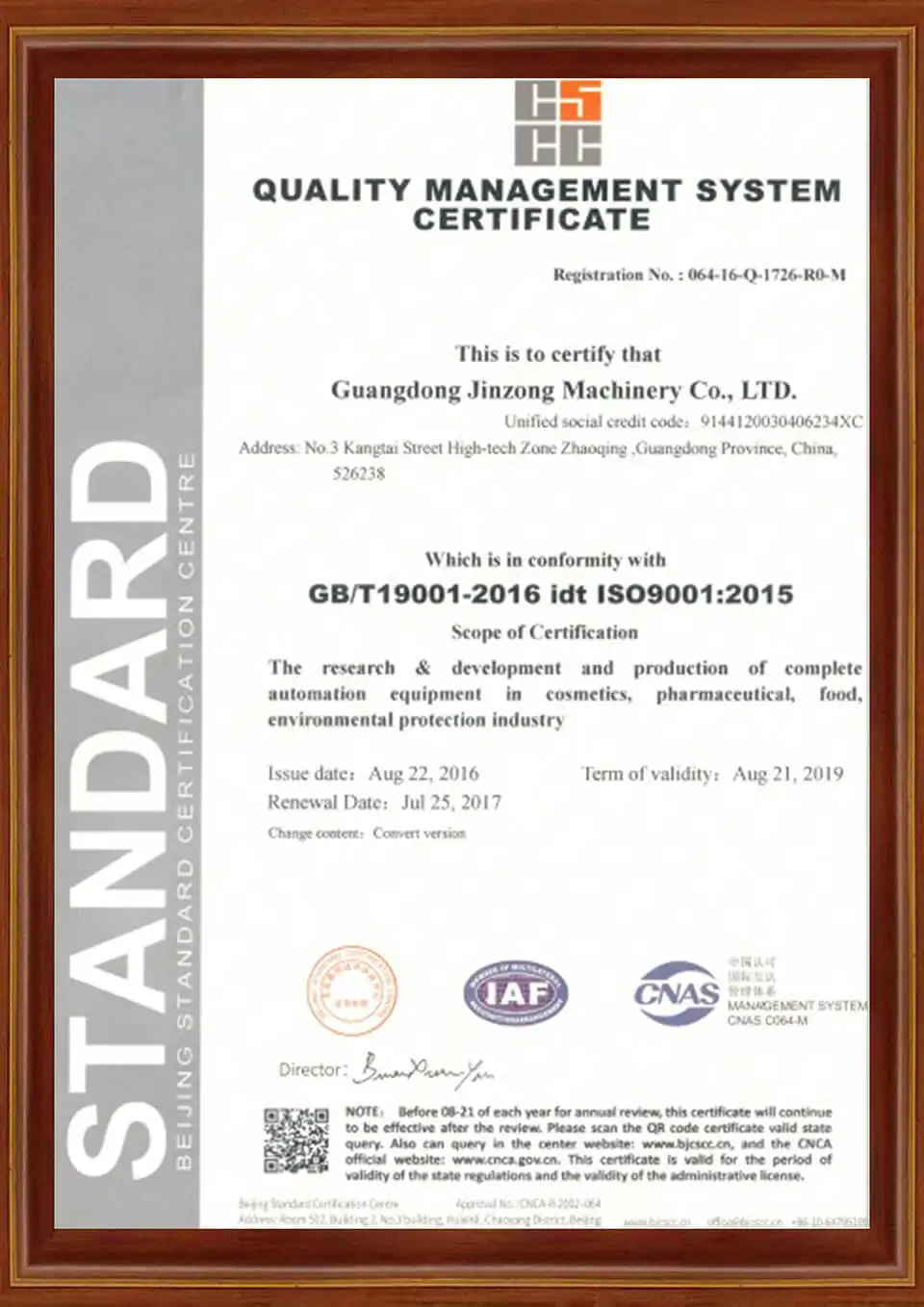

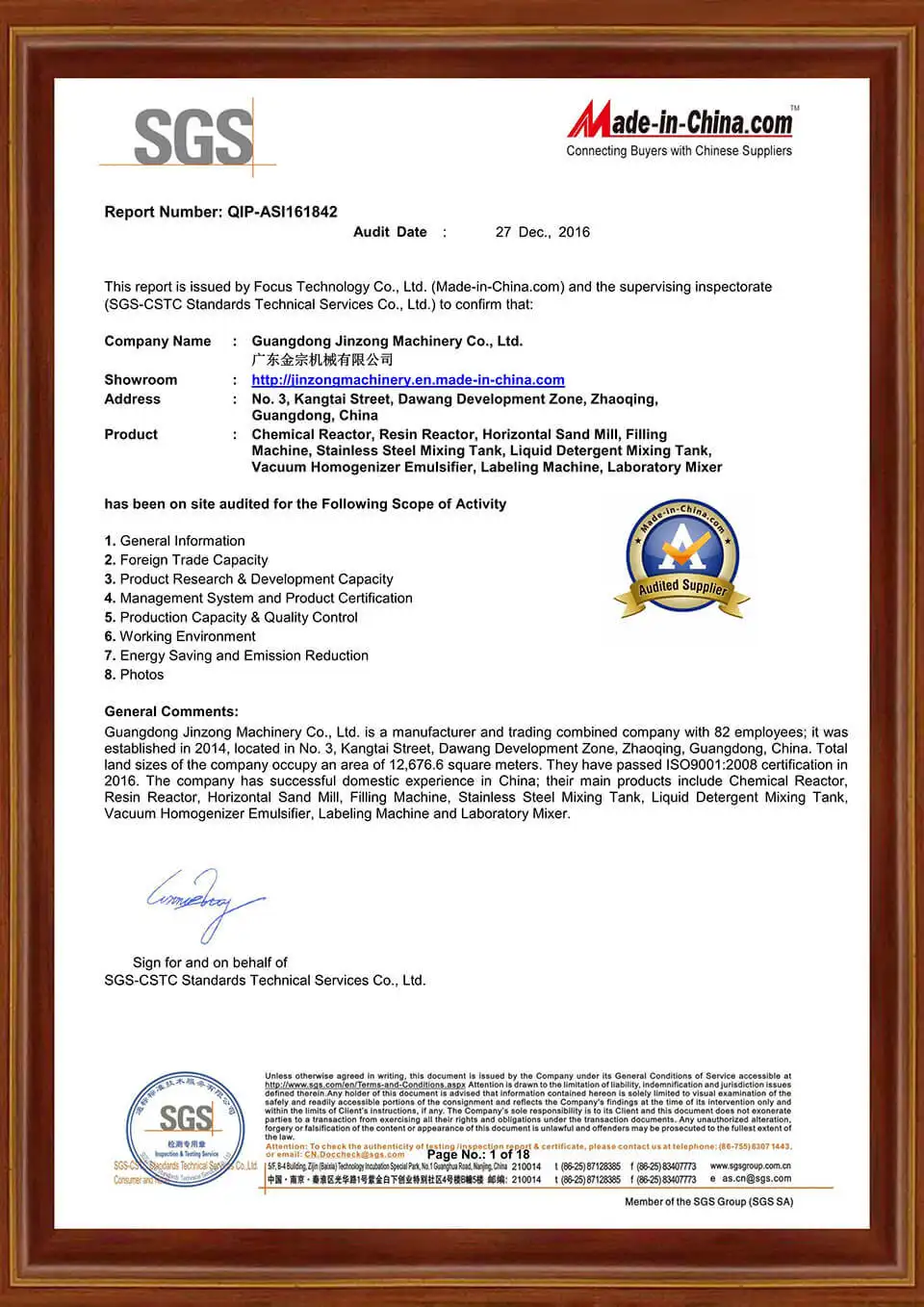

Company Features

1. Guangdong Jinzong Machinery Co., Ltd. is known as the backbone of the powder mixer field.

2. Owing to the sand mill machine technology, industrial powder mixer is manufactured to be of high quality.

3. Adhering to independent innovation, Jinzong Machinery has the ability to design and develop more and better powder mixer machine . Please contact us! Guangdong Jinzong Machinery Co., Ltd. promises milling machine warranty for one year, long-term after-sale spare parts service. Please contact us! We adhere to the concept of powder mixing equipment , achieving the value of both company and customers. Please contact us! Unswervingly implementing the strategy of strengthening powder mixer proves to be very essential. Please contact us!

| Item | Function |

| Material in charge hopper | for charging material to bucket elevator |

| Bucket elevator | Lifting materials to pre-mix silo |

| Biaxial agravic mixer | Mixing all materials |

| Finished product silo | for storing finished material and secondary mixing of pre-packing material. |

| Automatic packing machine | packing finished product by automatic weighing, high accuracy. |

| Pulse dust collector | absorb the dust during production process, mainly used for de-dust from material in-charge hopper and packer. |

| Control cabinet | includes instrumentation and PLC control for controlling electrical switch of the whole production lines. |

| Air compressor | Produce compressed air for the whole air compressing system |

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)