Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery utility Liquid Detergent Mixer high speed for paint and ink

1. Individualized design of Liquid Detergent Mixer has attracted many customers for now.

2. Jinzong Machinery has passed the quality management system to ensure the quality of the product.

3. The product has been tested on various quality parameters and has been proven to be high-quality.

4. The use of this product can help save people's energy costs and reduce carbon emissions. These benefits would last for many years.

5. Without the need for frequent maintenance and little power consumption, the product is a good way to save money for people.

*Application of Automatic Flat Bottles Labeling Machine:

1.Apply for labeling flat bottles,square bottles,round bottles.

2.For double sides labeling,one side labeling,around sides labeling

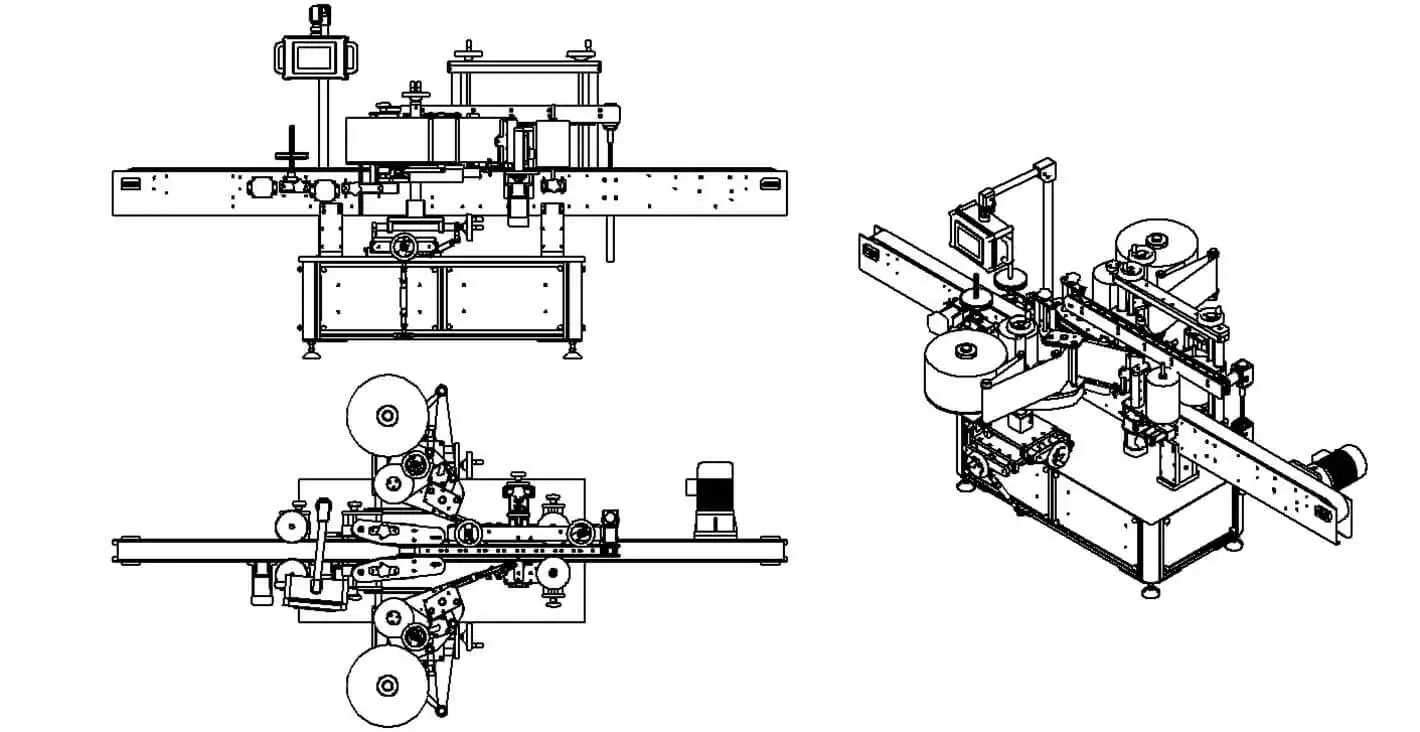

*Automatic Flat Bottles Labeling Machine Working Principle:

Put the bottles on the conveyor—Bottles separating-arrange/leading bottles-Labeling-press labels-finished

*Automatic Flat Bottles Labeling Machine Structure:

Main Motor: ①750W Panasonic servo motor; ②Panasonic servo amplifier ③Danfoss frequency inverter; ④Siemens PLC; ⑤Siemens touch screen ⑥German LEUZE labels sensor; ⑦Japan KEYENCE FS-V11 optoelectronic switch;

Conveyor: Motor 750W,speed adjustable by frequency inverter.

Bottles leading structure: Double coordinate adjustment stainless steel rail.

Plastic parts of the structure: Panasonic motor, speed adjustable, with the mechanical synchronous speed of the conveyor.

Press belt structure: Spiral Bevel Gear Drive,with the mechanical synchronous speed of the conveyor.

Scraper: Sponge spring steel plate combination.

Labels press structure: Combination unpowered sponge roller,Quick disassembling structure for different size of labels..

| NO. | Item | Specification |

| 1 | Labeling head number | 2pcs |

| 2 | Labels type | Adhesive sticker |

| 3 | Weight(height) of labels transporter | Max:200mm |

| 4 | Length of labels transporter | Max:400mm |

| 5 | Scraper | 20-200mm |

| 6 | Dimension of labeling object | thickness≤90mm height≤450mm or customer design |

| 7 | Labeling speed | 30-50m/min |

| 8 | Conveyor speed | 0-30m/Min |

| 9 | Capacity | 0-12000pcs/h |

| 10 | Tap location precision | ±0.2mm |

| 11 | Labeling precision | ±1mm |

| 12 | Label plate outside diameter | 350mm |

| 13 | Label plate inside diameter | 76.2mm |

| 14 | Qty of label plate | 2pcs |

| 15 | Size of Labels collector | 180mm |

| 16 | Method of labels collector | Rewind the labels |

| 17 | Conveyor belt | 950±50mm |

| 18 | Net weight | 500kg |

| 19 | Bottles conveying direction | From left to right |

| 20 | Labels conveying direction | From left to right |

| 21 | Dimension | L3048*W1400*H1650(mm) |

| 22 | Power supply | 220V/50Hz 3000W |

| Application labels | |

| Raw material of labels: | All the paper type labels,thin film type labels |

| Thickness of labels: | >2.5mm |

| The material of bottom labels: | Enough pull,the glassine or PET bottom labels will be better. |

| Label spacing requirement | Minimum spacing is 2.54mm,standard spacing is 3mm |

| Label size allowed error | ±0.3 mm |

| Max weight of labels: 200mm | < 200mm |

| Name | Item | Brand | Country | Units | Qty |

| PLC | S7-224 | Siemens | German | set | 1 |

| Touch Screen | Siemens | Taiwan | set | 1 | |

| Servo driver | MCDDT3520003 | Panasonic | Japan | set | 2 |

| Servo driver | MHMDD082P1U | Panasonic | Japan | set | 2 |

| Frequency inverter | FC-051PK | Danfoss | Danmark | set | 2 |

| a.c. contactor | LC1-D2510M7N | TELEMECANIQUE | German | set | 1 |

| Urgent stop switch box | 54*54 | TELEMECANIQUE | German | pcs | 1 |

| Urgent stop switch | XB2 ES542 | TELEMECANIQUE | German | pcs | 1 |

| Object sensor | FS-V11 | KEYENCE | Japan | set | 1 |

| Label sensor | GS63/6D.3-S8 | LEUZE | German | pcs | 2 |

| Power switch | 24V 6A | Meanwell | Taiwan | set | 1 |

| Conveyor motor | GV28-750-25S | Wanxin | Taiwan | set | 1 |

| Motor | M9MC60G4Y | Panasonic | Japan | set | 1 |

| Transmission | MGC30B | Panasonic | Japan | set | 1 |

| Speed controller | (includes insurance switch) | Panasonic | Japan | set | 1 |

Company Features

1. Guangdong Jinzong Machinery Co., Ltd. is a mixing tank supplier with rich industry experience.

2. Jinzong Machinery mastered high technology to produce Liquid Detergent Mixer .

3. Our goal is that we constantly deliver required business results, meet deadlines and comply with quality, productivity and performance standards. Our company is striving for green manufacturing. We choose materials carefully to ensure minimum indoor air emissions and maximize customers' ability to return materials to the resource stream once they have served their intended purpose. We work closely with our customers to find the perfect combination of products and services to achieve a comprehensive balance between performance and price effectiveness. We stick to sustainable processes. All emissions, whether gases, liquids, or solid and metal wastes, are monitored, treated where necessary, and sent for reuse or recycling wherever possible.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)