Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery practical automatic filling machine wholesale for petrochemical industry

- Jinzong receives wide recognition from customers and enjoys a good reputation in the industry based on sincere service, professional skills, and innovative service methods.

1. Jinzong Machinery cosmetic tube filling machine is the result of our excellence in detail. Its design incorporates aesthetic, functional and environmental considerations.

2. The product is inspected to industry standards to eliminate all defects.

3. This projector screen is perfect for outdoor birthday parties, wedding parties, poolside parties or simply a movie night party.

4. People who live in remote areas where electricity is not accessible will benefits a lot from this product because it powered fully from the natural sunlight.

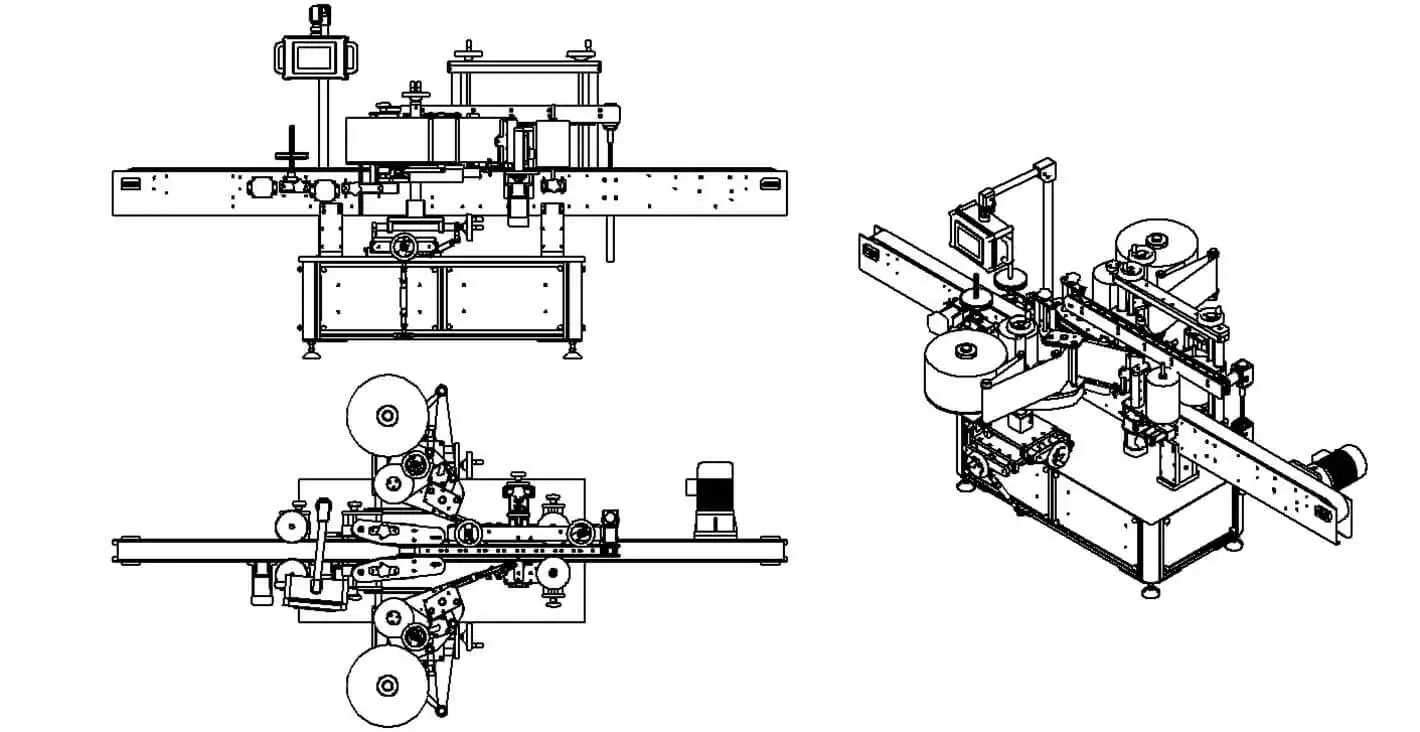

*Application of Automatic Flat Bottles Labeling Machine:

1.Apply for labeling flat bottles,square bottles,round bottles.

2.For double sides labeling,one side labeling,around sides labeling

*Automatic Flat Bottles Labeling Machine Working Principle:

Put the bottles on the conveyor—Bottles separating-arrange/leading bottles-Labeling-press labels-finished

*Automatic Flat Bottles Labeling Machine Structure:

Main Motor: ①750W Panasonic servo motor; ②Panasonic servo amplifier ③Danfoss frequency inverter; ④Siemens PLC; ⑤Siemens touch screen ⑥German LEUZE labels sensor; ⑦Japan KEYENCE FS-V11 optoelectronic switch;

Conveyor: Motor 750W,speed adjustable by frequency inverter.

Bottles leading structure: Double coordinate adjustment stainless steel rail.

Plastic parts of the structure: Panasonic motor, speed adjustable, with the mechanical synchronous speed of the conveyor.

Press belt structure: Spiral Bevel Gear Drive,with the mechanical synchronous speed of the conveyor.

Scraper: Sponge spring steel plate combination.

Labels press structure: Combination unpowered sponge roller,Quick disassembling structure for different size of labels..

| NO. | Item | Specification |

| 1 | Labeling head number | 2pcs |

| 2 | Labels type | Adhesive sticker |

| 3 | Weight(height) of labels transporter | Max:200mm |

| 4 | Length of labels transporter | Max:400mm |

| 5 | Scraper | 20-200mm |

| 6 | Dimension of labeling object | thickness≤90mm height≤450mm or customer design |

| 7 | Labeling speed | 30-50m/min |

| 8 | Conveyor speed | 0-30m/Min |

| 9 | Capacity | 0-12000pcs/h |

| 10 | Tap location precision | ±0.2mm |

| 11 | Labeling precision | ±1mm |

| 12 | Label plate outside diameter | 350mm |

| 13 | Label plate inside diameter | 76.2mm |

| 14 | Qty of label plate | 2pcs |

| 15 | Size of Labels collector | 180mm |

| 16 | Method of labels collector | Rewind the labels |

| 17 | Conveyor belt | 950±50mm |

| 18 | Net weight | 500kg |

| 19 | Bottles conveying direction | From left to right |

| 20 | Labels conveying direction | From left to right |

| 21 | Dimension | L3048*W1400*H1650(mm) |

| 22 | Power supply | 220V/50Hz 3000W |

| Application labels | |

| Raw material of labels: | All the paper type labels,thin film type labels |

| Thickness of labels: | >2.5mm |

| The material of bottom labels: | Enough pull,the glassine or PET bottom labels will be better. |

| Label spacing requirement | Minimum spacing is 2.54mm,standard spacing is 3mm |

| Label size allowed error | ±0.3 mm |

| Max weight of labels: 200mm | < 200mm |

| Name | Item | Brand | Country | Units | Qty |

| PLC | S7-224 | Siemens | German | set | 1 |

| Touch Screen | Siemens | Taiwan | set | 1 | |

| Servo driver | MCDDT3520003 | Panasonic | Japan | set | 2 |

| Servo driver | MHMDD082P1U | Panasonic | Japan | set | 2 |

| Frequency inverter | FC-051PK | Danfoss | Danmark | set | 2 |

| a.c. contactor | LC1-D2510M7N | TELEMECANIQUE | German | set | 1 |

| Urgent stop switch box | 54*54 | TELEMECANIQUE | German | pcs | 1 |

| Urgent stop switch | XB2 ES542 | TELEMECANIQUE | German | pcs | 1 |

| Object sensor | FS-V11 | KEYENCE | Japan | set | 1 |

| Label sensor | GS63/6D.3-S8 | LEUZE | German | pcs | 2 |

| Power switch | 24V 6A | Meanwell | Taiwan | set | 1 |

| Conveyor motor | GV28-750-25S | Wanxin | Taiwan | set | 1 |

| Motor | M9MC60G4Y | Panasonic | Japan | set | 1 |

| Transmission | MGC30B | Panasonic | Japan | set | 1 |

| Speed controller | (includes insurance switch) | Panasonic | Japan | set | 1 |

Company Features

1. Guangdong Jinzong Machinery Co., Ltd. is a China-based expert in providing high quality cosmetic tube filling machine for many years. We are very popular with overseas customers.

2. In terms of technology, Guangdong Jinzong Machinery Co., Ltd. has its own R&D team and intellectual property.

3. Facing the future, Jinzong Machinery adheres to the core concept of mixing tank . Check it! It is Guangdong Jinzong Machinery Co., Ltd.'s mission to significantly shorten the customer development cycle. Check it!

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)