Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

High energy Horizontal Intelligent Mamp Sand Mill2

1. The materials for manufacturing Jinzong Machinery sand mill manufacturers are carefully chosen. The selection is based on the demands of the building sector, so they are homogeneous and uniform in composition.

2. In comparing with other similar products, powder mixer has virtues of sand mill manufacturers .

3. powder mixer excels due to its merits of sand mill manufacturers .

4. Guangdong Jinzong Machinery Co., Ltd.'s products receive great trust and praise from the vast of customers for its excellent quality, low cost and good service.

5. Guangdong Jinzong Machinery Co., Ltd. has a higher product development capacity.

*Description:

Jinozng Horizontal Nanomills system combines the well-known special separation system designed by Jinzong. This agitator bead mill was specifically developed by Jinzong engineers for high energy, high flow, multiple pass and specifically circulation operation grinding to achieve very narrow submicron particle size distributions with excellent repeatability.

Mainly designed for the middle and small lot manufacture of middle and high class product.

Using solvent discharging valve gear in the small mill barrel can make no material draffy remain in the barrel consequently reduce the waste.

This machine is very economic for middle and small manufacture and can meet more requirement of customer.

The high precision separation device can use those mill beads which has small diameter and get high output.

| Type | IN-6 | IN-10 | IN-30 | IN-60 |

| Tank capacity(L) | 6 | 10 | 30 | 60 |

| Motor power(KW) | 15 | 22 | 45 | 75 |

| Production capacity(KG/h) | 40-200 | 100-500 | 500-2500 | 1000-6000 |

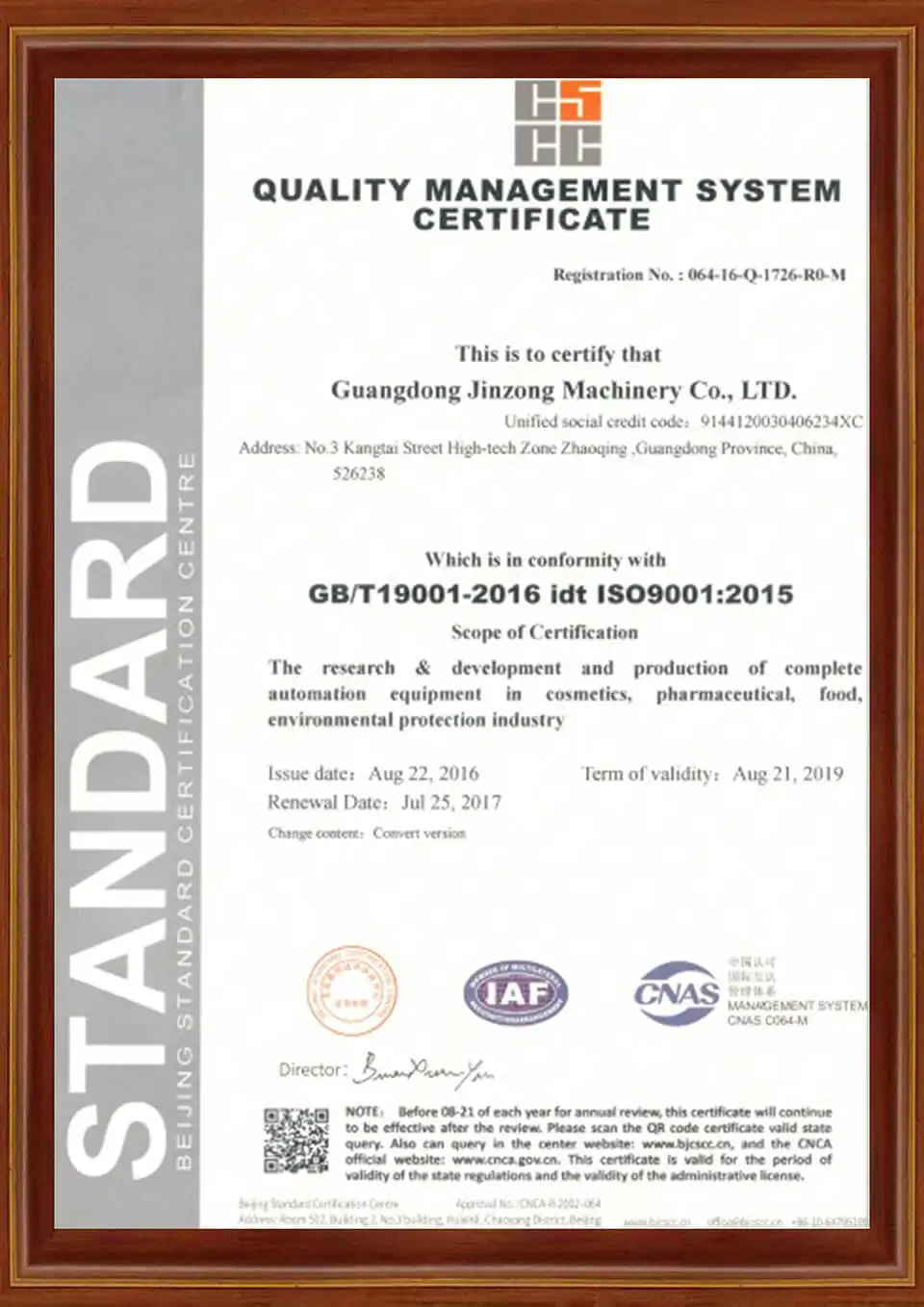

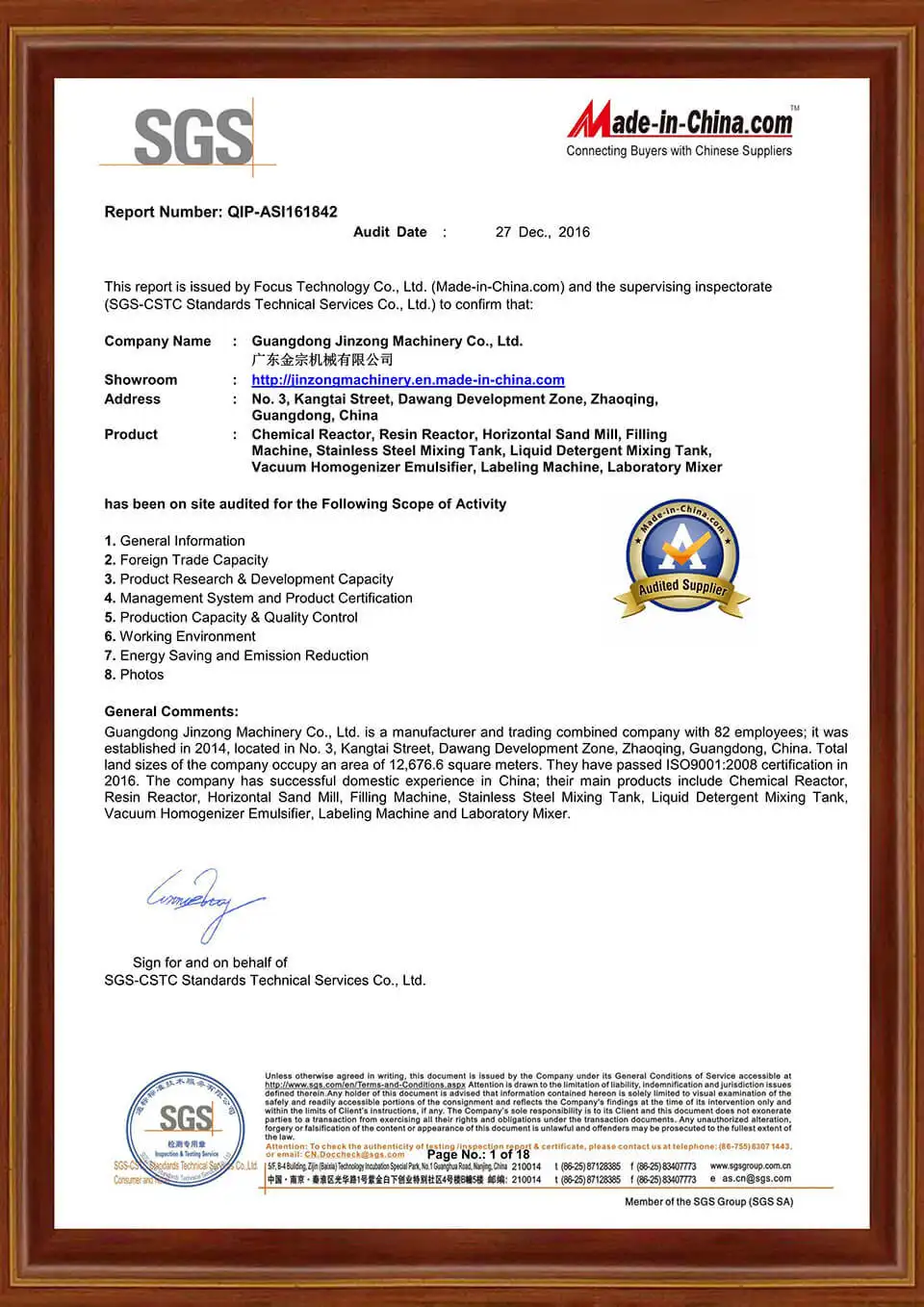

Company Features

1. Guangdong Jinzong Machinery Co., Ltd. now precedes in the Guangdong Jinzong Machinery Co., Ltd. industry.

2. Up until now, Guangdong Jinzong Machinery Co., Ltd. has possessed an outstanding systematic ability to develop new powder mixer products.

3. 'Protecting good quality' is Guangdong Jinzong Machinery Co., Ltd.'s brand promise. Contact us! High quality is always put in first place in Guangdong Jinzong Machinery Co., Ltd.. Contact us! Guangdong Jinzong Machinery Co., Ltd. has initiated the construction of corporate culture system including sand mill manufacturers . Contact us! Jinzong Machinery always seeks for development, self-breakthrough, and constant pursuit of high quality powder mixing equipment . Contact us!

Overview:

V-type mixer is carefully developed by our company based on foreign advanced technology and combined with our company's production experience. Widely used in the mixing of powder materials in the pharmaceutical, food, chemical, building materials industry, coatings, condiments and other industries.

working principle:

The V-shaped cylinder rotates around the center of the rotary shaft under the driving of the drive shaft, and the material therein also moves with the gravity of the two inclined cylinders of the V-shaped body. When the connection (bottom) of the V-shaped cylinder rotates, the V-shaped cylinder rotates. In the lower position, when the connection of the V-shaped cylinder is rotated at the upper position, the material collected at the bottom is shunted into the two inclined cylinders, so that the material of each inclined cylinder can enter the other obliquely through the joint interface. Inside the tube. As the cylinder rotates continuously and the position changes continuously, the material of the V-shaped cylinder is repeatedly misaligned, translated, and diffused, thereby achieving uniform mixing.

Features:

1. Mixing by gravity diffusion principle, the pressure feeding of the material is small, and the material will not be sheared and crushed.

2. The cylinder is made of high quality stainless steel, the inner and outer walls are polished, no pollution to the material during mixing, low power consumption and convenient cleaning.

3. The stainless steel butterfly valve is used for discharging, no dust leakage and flying phenomenon appear.

4. The large volume mixer can be equipped with a vacuum loading system to improve work efficiency and improve the working environment.

5. It is especially suitable for material mixing between particles and apparent density.

In the V-type mixer rotary axis, a mandatory mixing blade can be added in the V-shaped cylinder to speed up the mixing speed, and it can also be applied to the mixing of easily condensed materials.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)